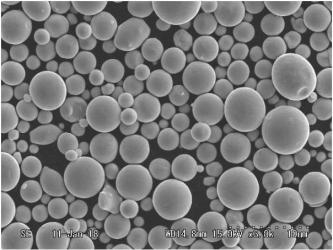

Vacuum Induction Gas Atomization for Alloy Metal Powder

Metal powder production can be classified as atomization, mechanical comminution. The atomization method can produce the highly spheroidized and flowability metal powder which can be applied for 3D printing, Thermal spray. We have air classifier to control particle size as customer’s requirement.

Application

- Sputtering Target: Si-Al, Cu-Ga, NiCrAl, Cr-Si, Co-Cr, Ni-Cr

- Thermal spray: NiCrBSi, CoCrBSi

- Electromagnetic Interference (EMI): NiFeAl, FeNiCu

- Magnetic materials: FeCoCr, FeCoTaCr, FeCoCrB, NiFe, FeAlSi, FeSi

- Special Steel: M2 tool steel, 316L stainless steel

- 3D printing: ASTM F75 (CoCrMo)

Product Advantages

- By controlling atomization temperature, gas press to obtain high efficiency and performance products.

- Accurate chemical composition, uniform alloy composition.

- Uniform particle size distribution, excellent powder fluidity and formability.

Main Products

Thin film sputtering tube/ plate target, metal powder for 3D printing, acid and alkali-resistance alloy and titanium for cooking/ tableware. Sputtering target bonding, precious metal recycling, Vacuum hot pressing sintering, forging and analysis

Related Products

Contact Detail

-

AddressNo.1, Luke 8th Rd., Lujhu District, Kaohsiung, Taiwan R.O.C.

-

Tel+886-7-6955125

-

Fax+886-7-6955205

-

E-mail

-

URL

ThinTech Materials Technology Co., Ltd.

ThinTech Materials Technology Co., Ltd.