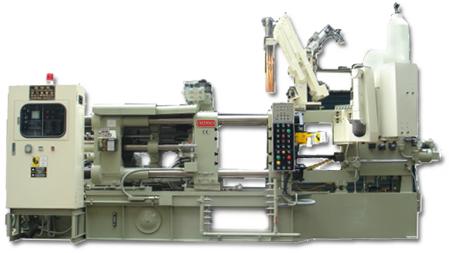

Automatic Die Casting Machine and peripheral equipment, Clamping force form 100t to 1000t.

Products covered: Car/motorcycle parts, transportation facilities, home appliances, architectural metal ware, electrical equipment, telecommunication equipment, precision instruments, industrial machines and office machines.

Products covered: Car/motorcycle parts, transportation facilities, home appliances, architectural metal ware, electrical equipment, telecommunication equipment, precision instruments, industrial machines and office machines.

Features

- By applying low hydraulic pressure, the temperature of oil will not rise (maintained at 48-50 degree). With low failure rate of the parts, long lifetime of the machine is certain.

- When the machine is inactive, zero loading will be applied to hydraulic device, which will save 30% of electric power.

- Effective pressure intensification, which can increase the pressure 2-3 times higher, will achieve an absolute result of pressure rise.

- The absolutely effective injection and powerful injection force are the major advantages of our die-casting machine.

- Automatic mold setup and mold thickness adjustment can initiate the production status for the die casting in the shortest period of time.

- Complete design can increase 30% of yield per hour.

- P.L.C. control is implemented, so the machine is easy to operate and perform maintenance (oneself manual maintenance is also allowed)

- To fulfill the yield requirements for our customers, the machine can operate without stopping for a long period of time.

| . | Item | Unit | CH100CI | CH150CI | CH200CI | CH250CI |

|---|---|---|---|---|---|---|

| Clamping System | Clamping force | ton | 100 | 150 | 200 | 250 |

| Clamping System | Die plate dimension | mm | 600*600 | 720*720 | 770*770 | 820*820 |

| Clamping System | Tie bar distance | mm | 390*390 | 460*460 | 500*500 | 530*530 |

| Clamping System | Die height, max | mm | 450 | 540 | 560 | 600 |

| Clamping System | Die height, min | mm | 180 | 200 | 220 | 250 |

| Clamping System | Die stroke | mm | 240 | 290 | 300 | 340 |

| Clamping System | tie bar diameter | mm | 80 | 90 | 95 | 100 |

| Injetion System | Shot force | ton | 11.5 | 16 | 22.5 | 25 |

| Injetion System | Intensifier | kg/cm | 250 | 250 | 250 | 250 |

| Injetion System | Plunger storke | mm | 350 | 350 | 410 | 420 |

| Injetion System | Plunger tip penetration | mm | 130 | 130 | 155 | 160 |

| Injetion System | Standard plunger tip diameter | mm | 40-60 | 40-60 | 50-70 | 50-70 |

| Ejection System | Ejecting force | ton | 9.5 | 10.5 | 15 | 16 |

| Ejection System | Ejecting stroke | mm | 80 | 80 | 95 | 100 |

| Ejection System | Ejecting time(abjustable) | sec | 0-999 | 0-999 | 0-999 | 0-999 |

| Ejection System | Ejecting time(abjustable) | sec | 0-999 | 0-999 | 0-999 | 0-999 |

| Neutron System | Electromagnetic valve | PT | 2 Set | 2 Set | 2 Set | 2 Set |

| Neutron System | Oil take-out port | PT | 1/2" | 1/2" | 1/2"-3/4" | 1/2"-3/4" |

| Neutron System | Plug socket | -- | 4 Set | 4 Set | 4 Set | 4 Set |

| Hydraulic system | Die pressure | kg/cm | 15-120 | 15-120 | 15-120 | 15-120 |

| Hydraulic system | Ejectibg pressure | kg/cm | 80-140 | 80-140 | 80-140 | 80-140 |

| Hydraulic system | Intensifier pressure | kg/cm | 100-250 | 100-250 | 100-250 | 100-250 |

| Hydraulic system | Pump pressure | kg/cm | 140 | 140 | 140 | 140 |

| Hydraulic system | Accumulate model and quantity | L/T | 40/T | 40/T | 40/T | 40/T |

| Hydraulic system | Colling water | 1/min | 350 | 350 | 350 | 350 |

| Electric System | Control system | Japan script | P.L.C | P.L.C | P.L.C | P.L.C |

| Electric System | Motor | HP | 15HP | 15HP | 15HP | 20HP |

| Electric System | Power source | V | 220-380 | 220-380 | 220-380 | 220-380 |

| Electric System | Control panel size(L*W*H) | mm | 800*360*1400 | 800*360*1400 | 800*360*1400 | 800*360*1400 |

| Machine Size | Weight | ton | 4.2 | 5.6 | 6.8 | 9.8 |

| Machine Size | Machine size | mm | 4400*1500*1950 | 4800*1620*2100 | 5000*1680*2300 | 5700*1760*2600 |

| Machine Size | Delivery date | day | 40 | 40 | 40 | 60 |

Main Products

die casting machine,vacuum machine,automatic ladle machine,melting holding furnace,electrice melting holding crucible furnace,mold temperature controller