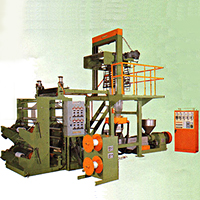

PE wrapping film making machine is available for producing PE cling film & PE stretch film for home & industrial using. We develop pump inlet adhesion technology to inlet the adhesion into screw, so that you can set percentage of adhesion you need, besides, you can save the resin cost. The screw can provide excellent mixing result to mix resin & adhesion. The take-up unit & winder are controller by co-speed controller to keep the same speed & avoid the film be stretched to get good and standard film quality. This machine also can change to 2-layer co-extrusion to produce one layer sticky & one layer non-sticky.

Features

- Special design screw makes sure the excellent mixing of material & adhesion

- Using pump inlets the adhesion to save resin cost

- Co-speed controller keeps the film in standard quality

| Model No. | WPE-45H | WPE-55H | WPE-65H |

|---|---|---|---|

| Raw Material | LLDPE, LDPE | LLDPE, LDPE | LLDPE, LDPE |

| Roller Width (mm) | 750 | 900 | 1200 |

| Layflat Width (mm) | 200-600 | 250-800 | 300-1100 |

| Film Thickness (mm) | 0.008-0.08 | 0.008-0.08 | 0.008-0.08 |

| Output (kg/hr.) | 15-50 | 20-70 | 25-90 |

| Output depending on film width, thickness, die size, material property etc. | Output depending on film width, thickness, die size, material property etc. | Output depending on film width, thickness, die size, material property etc. | Output depending on film width, thickness, die size, material property etc. |

| Power Required (kw) | 42 | 56 | 72 |

| Machine Dimension (m) | 6.2 x 2.4 x 4.1 | 6.3 x 2.6 x 4.2 | 6.6 x 2.9 x 4.5 |

| PERFORMANCE | PERFORMANCE | PERFORMANCE | PERFORMANCE |

| Gear Box | Surface heat quenching & tempering equipped w/oil auto. Lubricated sys. | Surface heat quenching & tempering equipped w/oil auto. Lubricated sys. | Surface heat quenching & tempering equipped w/oil auto. Lubricated sys. |

| Gear | Heat quenching & grinding treatment | Heat quenching & grinding treatment | Heat quenching & grinding treatment |

| Screw Material | Alloyed steel, hard chrome plated and nitrided | Alloyed steel, hard chrome plated and nitrided | Alloyed steel, hard chrome plated and nitrided |

| Barred Material | Alloyed steel, polished and nitrided treatment | Alloyed steel, polished and nitrided treatment | Alloyed steel, polished and nitrided treatment |

| Air Ring | Alum. Alloyed, special desing for providing excellent & stable cooling | Alum. Alloyed, special desing for providing excellent & stable cooling | Alum. Alloyed, special desing for providing excellent & stable cooling |

| EXTRUDER | EXTRUDER | EXTRUDER | EXTRUDER |

| Screw Diameter (mm) | 45 | 55 | 65 |

| Screw Ratio (L/D) | 28: 1 | 30: 1 | 30: 1 |

| Drive Moter (HP) | V.S. 25 | V.S. 40 | V.S. 50 |

| Die Type | Rotary die w/rotary air ring | Rotary die w/rotary air ring | Rotary die w/rotary air ring |

| Die Diameter (mm) | 200 | 250 | 300 |

| Rotary Drive Motor | 1/2 HP | 1 HP | 1 HP |

| Die Temp. Controller | 2 zones | 2 zones | 2 zones |

| Blower (HP) | 5 | 5 | 5 |

| TAKE-UP UNIT | TAKE-UP UNIT | TAKE-UP UNIT | TAKE-UP UNIT |

| Type | fixed twoer w/adjustable movable take-up unit | fixed twoer w/adjustable movable take-up unit | fixed twoer w/adjustable movable take-up unit |

| Motor (HP) | 1 HP W/Reducer | 1 HP W/Reducer | 1 HP W/Reducer |

| Take-Up Height (mm) | 4100 | 4200 | 4500 |

| Split Roller (set) | 1 | 1 | 1 |

| Split Knife (pcs) | 3 | 3 | 3 |

| WINDER | WINDER | WINDER | WINDER |

| Type | surface friction type & back-to-back w/four winding reels | surface friction type & back-to-back w/four winding reels | surface friction type & back-to-back w/four winding reels |

| Roller Width (mm) | 750 x 2 sets / 500 x 2 sets | 900 x 2 sets / 650 x 2 sets | 1200 x 2 sets / 900 x 2 sets |

| Winding Motor (kg/cm) | 1 HP x 4 sets w/reducer | 1 HP x 4 sets w/reducer | 1 HP x 4 sets w/reducer |

| Winding Diameter (mm) | 700 x 2 sets | 700 x 2 sets | 700 x 2 sets |

| Spare Waste Collector (HP) | 1/2 HP | 1/2 HP | 1/2 HP |

| Waste Collector (set) | 2 sets | 2 sets | 2 sets |

| Waste Collector Motor (kg/cm) | Torque 10 x 2 sets | Torque 10 x 2 sets | Torque 10 x 2 sets |

| TEMPERATURE CONTROL | TEMPERATURE CONTROL | TEMPERATURE CONTROL | TEMPERATURE CONTROL |

| Heating Zone | 5 | 5 | 6 |

Main Products

Plastic Machinery, Extruder, PE or PP or PVC Film Whole Plant, PE Cling / Stretch Film Equipment For Food or Industry Packing, PE Shrinkable Film Making Machine, T-Die Extrusion for Baby Diaper or Women Sanitary Napkin, PE / PP Normal Sheet, PE Foam Sheet, 2 / 3-Layer Co-Extrusion, 2 / 3 / 4 Color B