1)Patch handle bag is a shopping bag with polyethlene film attached to the top of the PE bags by means of heat-sealing.

2)Die cut handle bag is a shopping bag with punched hole for handle at the top folding & top sealing area. With or without bottom gusset.

3)Draw tape bag is a garbage bag with a roll of narrow plastic film inserted automatically into the top folding & top sealing area. With or without bottom gusset.

4)Triangle Folding Device (option): Triangle folding device can be purchased for folding single sheet film to run in-line with the machine. The unwind stand is equipped with E.P.C.(Edge Position Control) for accurate folding. The unwind stand is also equipped with powder brake. The maximum reel diameter is 70cm. Maximum reel weight is 150kgs.

5)Handle Punching Device: The pneumatically controlled handle punching device is equipped with knife type cuter which is designed for long duration and easy maintenance.

6)The Manufacture Of The Patch Handle Shopping Bag: The patch handle film feeding system is driven pneumatically. The small roll of PE film (W: 150mm, Thickness: 0.11-0.13mm) is fed, cut and welded automatically to the top central position of the PE shopping bag.

Air transmitting system is good for easy maintenance. Rotary system for patch film sealing increase the production speed.

7)The Manufacture Of The Draw Tape Garbage Bags: The film for the draw tape should be pre-slit by setting machine and automatically fed into the top folds of the shopping bag by draw tape inserting device.

8)Top Sealing Device(Lip Sealing): Top sealing device consists of two sealing bars, up and down, are both heated and pneumatically moved toward each other in every welding cycle and then separated.

2)Die cut handle bag is a shopping bag with punched hole for handle at the top folding & top sealing area. With or without bottom gusset.

3)Draw tape bag is a garbage bag with a roll of narrow plastic film inserted automatically into the top folding & top sealing area. With or without bottom gusset.

4)Triangle Folding Device (option): Triangle folding device can be purchased for folding single sheet film to run in-line with the machine. The unwind stand is equipped with E.P.C.(Edge Position Control) for accurate folding. The unwind stand is also equipped with powder brake. The maximum reel diameter is 70cm. Maximum reel weight is 150kgs.

5)Handle Punching Device: The pneumatically controlled handle punching device is equipped with knife type cuter which is designed for long duration and easy maintenance.

6)The Manufacture Of The Patch Handle Shopping Bag: The patch handle film feeding system is driven pneumatically. The small roll of PE film (W: 150mm, Thickness: 0.11-0.13mm) is fed, cut and welded automatically to the top central position of the PE shopping bag.

Air transmitting system is good for easy maintenance. Rotary system for patch film sealing increase the production speed.

7)The Manufacture Of The Draw Tape Garbage Bags: The film for the draw tape should be pre-slit by setting machine and automatically fed into the top folds of the shopping bag by draw tape inserting device.

8)Top Sealing Device(Lip Sealing): Top sealing device consists of two sealing bars, up and down, are both heated and pneumatically moved toward each other in every welding cycle and then separated.

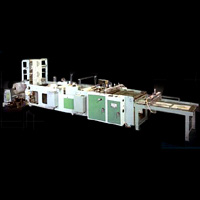

| Model | HSW-32PDD |

|---|---|

| Min. Bag Length | 250mm / 9.8" |

| Max. Bag Length | 650mm / 25.6" |

| Min. Bag Width | 250mm / 9.8" |

| Max. Bag Width | 750mm / 30" |

| Top Folding | 70mm ~ 75mm |

| Bottom Gusseting | Up to 85mm |

| Sealing thickness | 0.045 ~ 0.09mm |

| Production Rate | 40 ~ 60 bags/min |

| Electrical Requirement | 8.8KW |

Main Products

High Speed Bag Making Machine, Efficient Bottom Sealing Bag Making Machine, High Speed Bags On Roll Making Machine, Side Sealing Bags Making Machine, Irregular Shapes Bags Making Machine