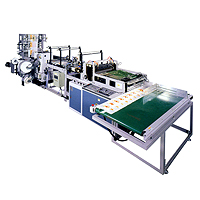

1. These "HP - SW" series machines are specially designed for the making of value added & special plain & printed side welded bags. Just by attaching different devices, many special side welded bags (link patch handle bags, soft loop handle bags, poly draw bags...etc) can be made by these "HP - SW" series machines.

2. With one set Germany made "sick" brand mark sensor (with "miss registration" alarm function) for precise print registration.

3. All the temperature controllers are with "lower than pre - set temperature" alarm function to ensure the finished bags quality.

4. Equipped with 2 sets of sealing bars (one set for per material, the other set for PP / BOPP material).

5. Using silicone material conveyer belts.

6. Equipped with 2 sets conveyer motors for 2 - steps conveyer belts' driving, these 2 sets conveyer motors' speed is controlled by "twin - clutch device" to ensure very smoothly finished bags' stacking.

7. For saving the machine's installation space, increasing the production efficiency, reducing the machine's maintenance cost and easy operation, the "HP - SW" series machines are specially designed to be able to be interchangeable for the main optional attachments' installation (like patch handle bags device, soft loop handle bags, poly draw bags...etc).

8. The following devices are standard attachments for the "HP - SW" series machines to make the following 15 different kinds of side welded bags:

(A) Side slitter.

(B) Bottom gusseting device.

(C) Lip device (for both outside lip and inside lip).

(D) Center slitter.

2. With one set Germany made "sick" brand mark sensor (with "miss registration" alarm function) for precise print registration.

3. All the temperature controllers are with "lower than pre - set temperature" alarm function to ensure the finished bags quality.

4. Equipped with 2 sets of sealing bars (one set for per material, the other set for PP / BOPP material).

5. Using silicone material conveyer belts.

6. Equipped with 2 sets conveyer motors for 2 - steps conveyer belts' driving, these 2 sets conveyer motors' speed is controlled by "twin - clutch device" to ensure very smoothly finished bags' stacking.

7. For saving the machine's installation space, increasing the production efficiency, reducing the machine's maintenance cost and easy operation, the "HP - SW" series machines are specially designed to be able to be interchangeable for the main optional attachments' installation (like patch handle bags device, soft loop handle bags, poly draw bags...etc).

8. The following devices are standard attachments for the "HP - SW" series machines to make the following 15 different kinds of side welded bags:

(A) Side slitter.

(B) Bottom gusseting device.

(C) Lip device (for both outside lip and inside lip).

(D) Center slitter.

Main Products

Film Blowing Machine or Extruder, Flexographic Printing Machine, Rotogravure Printing Machine, Sealing and Cutting Machine