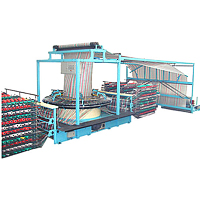

4-shuttle Circular Loom

Woven Bag Making Machine

Circular Loom

Product ID: GS-YZJ-4-2, GS-YZJ-4-3, GS-YZJ-4-750, GS-YZJ-6-2, GS-YZJ-6-1350, GS-YZJ-6 (Large), GS-YZJ-8

Send Inquiry

Researched and manufactured by assimilating German, Japanese and Formosan technology, machines of this type controlled by micro-computer are equipped with automatic warp transmission unit, automatic broken weft detector and change-speed clutch compensation device. Oil-pump can supply oil automatically and is also equipped with off-oil protecting unit. Woven bags are applied to pack cement, fertilizer, rice, flour, vegetables and other light products. These machines have many traits such as convenience in maintenance, high output, especially non-oil rolling shuttle type which can reduce energy consumption by 30% and can also make woven bags without oil pollution easy to coat and print.

Specifications

- For making the PP woven bag and the Bulk Bag

- The 4 shuttles circular loom with Bags width 250-750mm

- Model: GS-YZJ-4-3B

- Quantity of shuttle: 4

- Power of Main Motor: 2.2 Kw

- Output per Eight Hours: 600-800m / 8hours

- The 6 shuttles circular loom with Bags width 400-880mm

- Model: GS-YZJ-6-2

- Quantity of shuttle: 6

- Power of Main Motor: 3 Kw

- Output per Eight Hours: 800-850m / 8hours

- The 8 shuttles circular loom with Bags width 400-880mm

- Model: GS-YZJ-8

- Quantity of shuttle: 8

- Power of Main Motor: 11 Kw

- Output per Eight Hours: 200-550m/8hours

- I think the above two both could meet your requirements, what is you choice

| plastic machinery | packaging mahcinery |

|---|

Main Products

Plastic Machinery, Circular Loom, PP Woven Bag Production Line, Plastic Bag Making Machine, Plastic Extruder, Extruder For PP Tape Line, Extrusion Plant, PP Woven Bag Machinery, PP Yarn Extruding and Stretching Machine, Woven Bag Circular Loom, Mesh Bag Leno Loom, PP Leno Bag machinery, HDPE Film Bl