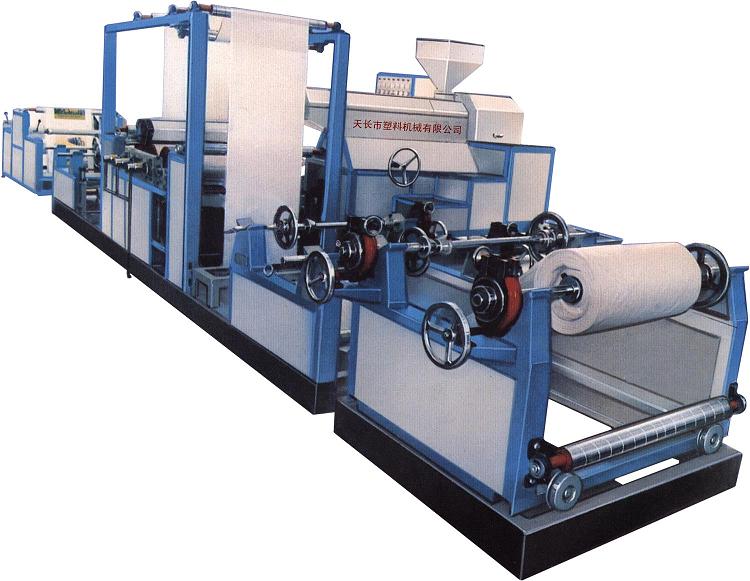

Laminating Machine

Coating Machine

The Plastic Laminating machine is making use of the good adhesive property of polypropylene and polyethylene during the melting status, this machine adheres and laminates paper and color-printed woven packaging bags. Laminating melted polypropylene and polyethylene film on woven bags produces laminated woven bags. Laminating on the film and paper directly, or laminating color-printed OPP and BOPP film on both sides of these bags produces colored packaging bags for instant noodles, melon seeds and various other foods.

Specifications

- BOPP laminating woven bag plant

- Most professional manufacturer for PP woven bag machinery, Circular loom, PP yarn extruder, PP woven bag cutting &sewing machine etc.

- Main Technical Parameter

- Model: SFA/B850

- Number of die 2 Dies

- Width of the Mould Head: 800mm

- Width of the Roller: 850mm

- Max. Coating width (mm): 700mm

- Film Thickness: 0.01-0.05mm

- Coating speed: 8-90m/min

- Number of Coating Layer: 2-6

- Diameter of The Screw: Φ65mm

- Ratio of Length to Diameter of Screw: 28 : 1

- Heating Power: 35kW

- Power of extruder motor: 25kw

- Total Power: 60kW

- Installing Size: 13000?000?500mm

- Approx Weight: 11.5 T

Features

- Multifunction Laminating Machine

- It is suitable for coating on the Circular PP/HDPE Woven Fabric

Main Products

Plastic Machinery, Circular Loom, PP Woven Bag Production Line, Plastic Bag Making Machine, Plastic Extruder, Extruder For PP Tape Line, Extrusion Plant, PP Woven Bag Machinery, PP Yarn Extruding and Stretching Machine, Woven Bag Circular Loom, Mesh Bag Leno Loom, PP Leno Bag machinery, HDPE Film Bl