Excellent Impact Strength Outstanding Temperature Range.

High Clarity and Gloss

Flame Resistance and Retardance

Low Conductivity

Non-toxicity

High Clarity and Gloss

Flame Resistance and Retardance

Low Conductivity

Non-toxicity

Specifications

- HWPC120T1400

- FUNCTION OF EQUIPMENTS ------

- Product:PC/PMMA Sheet

- Thickness:1.6~6.0m/m

- Length:free from any chosen length by customer

- Max. Width:1300m/m

- Max. output:220kg/hr.(PC),250kg/hr.(PMMA)

- EXTRUDER ------

- Type:Vented downward type extruder

- L/D Ratio:32/1

- Screw Material:SCM-440 alloysteel with nitrided, hard chromed treatments.

- Barrel Material:AISI 4140 imported from USA particularly for processing PC.

- Barrel Temperature Control: 6 zones, 49.5kw

- Option:Auto Loader

- MAIN DRIVING SYSTEM ------

- Motor:200HP DC Drive

- Motor Revolution:90~1800 r.p.m.

- SCREEN CHANGER ------

- Type:Sliding plate type hydraulic system

- Hydraulic Pump:5HP x 1 set

- T-DIE ------

- Type:Imported flat type sheeting extrusion die

- Die Width:1400m/m

- Die Lip:2.0m/m or 4.0m/m or 6.0m/m

- Die Temperature Control: 7 zones, 23kw

- GEAR PUMP ------

- Type:Imported grade

- Volume:92.6C.C.

- Drive:20 HP DC motor

- Pressure transducer, indicator and display meter W/Feeding-Back device x 1 set

- ROLL STACK ------

- Type:Imported grade mirror finishing roller in 45 degree slant alignment.

- Roller Dimension:425m/m x 1600m/m x 3 pcs.

- Drive:5HP DC motor + 1/60 reducer

- Hydraulic Pump:5HP

- Temperature Control of Heating Tank:3 sets

- By means of individual thermal display & control operative device

- ROLLER PASSAGE ------

- Type:By means of steel finishing roller

- Bridge Length:6000m/m x 1600m/m(w)

- Roller Dimension:160m/m x 1550m/m(w)

- Drive:1HP DC + 1/30 reducer

- COATING UNIT ------

- Type:double sides film protective coating

- Heater Capacity:6kw

- HAUL-OFF & EDGE TRIMMING UNIT ------

- Roller:160m/m x 1600m/m(w)

- Drive:5HP DC + 1/60 reducer

- Trimming:Pneumatic control saw x 2 pcs.

- Dust Collector:Vacuuming motor 10 Hp x 1 set(dust collecting tank included)

- CUTTING UNIT ------

- Type:Movable stainless steel saw x 1 set

- Sliding Rail:Imported grade, pneumatic control driven by 2HP AC motor x 1 set

- CONVEYING SYSTEM ------

- Type:Rubber belt conveyor stack x 1 set

- Drive:1HP DC

- Vacuum Sucker:5HP x 1 set

- Digital Counter:1 set with alarm

- Movable Distance of Vacuum Sucker:1800m/m

- ELECTRICAL CONTROL PANEL ------

- Isolated control panel. High grade electrical parts are used for controlling, operating, indicating system

- MACHINE DIMENSION:20634(L) x 4850(W) x 2500(H)m/m

- *********************************************************************

- YE I Reserves The Right To Change Specifications Or Materials For Improvement Without Prior Notification.

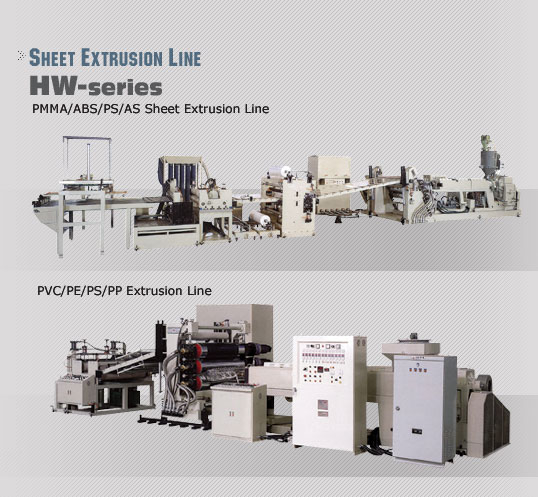

Main Products

Extruders, PE & PP Blown Film Machines,Plastic waste recycling machine,plastic recycling machine,extrusion Lamination machine,tubular film blown machinery,sheeting extrusion machine,sheet extrusion machine,Plastic waste recycling plant series,Machinery of above turnkey plant,Manufacturer of Extrusio

Contact Detail

-

Sales ContactLin Chun Jung

-

Address6, MIN DUNG RD. YEONG KANG CITY, TAINAN COUNTY,TAIWAN ,R.O.C.

-

Tel886-6-2536066

-

Fax886-6-2543717

-

E-mail

-

URL