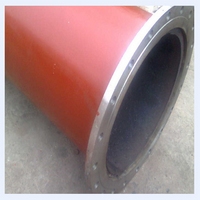

wear resisting pipes

1. Lower Cost than the Cast Iron Pipe and Alloy Steel Pipe

2.Low Weight and Convenient installation

3.Unique Abrasion Resistant

4.Excellent Corrosion Resistant

5.Smooth Inner Wall

2.Low Weight and Convenient installation

3.Unique Abrasion Resistant

4.Excellent Corrosion Resistant

5.Smooth Inner Wall

Specifications

- Manufacturing of Ceramic Lined Pipe

- Ceramic (Corundum: a-Al2O3) lined abrasion resistant straight pipe and

- fittings. The pipe and fittings are lined with highly abrasion resistant ceramic

- by Self-propagating High-temperature Synthetic process. They are widely used to

- convey highly abrasive material such as fly ash and any other fine powder

- material in mine, thermo power generating, coal processing plant,

- matellurgy,construction,etc. The service life is 10 to 20 times longer than

- normal steel pipe.

- Specification

- 1Size :76mm-1020mm

- 2.Wall Thickness:9mm-27mm

- 3.Outside Housing Material:Carbon Steel Seamless Pipe

- 4.Inner Material:Alumina Ceramic

- 5.Ceramic Lining Thickness(Including Transition Layer):3mm to 7mm

- 6.Normal Operation Temperature: -50℃--800℃

- 7.Normal Operation Velocity:20-35m/s

- 8.Length:1m 2m 3m

- Characteristics

- 1.High abrasion resistance

- 2 Thermal shock resistance

- 3.Corrosion resistance

- 4.Inner lining is inorganic oxide with a Rockwell Hardness of not less than 80HRA.

- 5 Good resistance to a wide range of chemicals including diluted acids, alkalis and solvents.

- 6.Operating temperature can reach 170-350Celsius degree.

- Product Application

- Mine

- Steel Industry

- Coal Industry

- Thermal power

- Cement Industry

- Smelting Industry

- Chemical Industry

- Mechanical Industry

Main Products

ceramic lined pipe ,abrasion resistant pipe,concrete pump parts