1.Size :40mm-630mm

2.Wall Thickness:8mm-20mm

3.Outside Housing Material:Carbon Steel Seamless Pipe

4.Inner Material:Alumina Ceramic

5.Ceramic Lining Thickness(Including Transition Layer):3mm to 7mm

6.Normal Operation Temperature:-50℃--800℃

7.Normal Operation Velocity:20-35m/s

2.Wall Thickness:8mm-20mm

3.Outside Housing Material:Carbon Steel Seamless Pipe

4.Inner Material:Alumina Ceramic

5.Ceramic Lining Thickness(Including Transition Layer):3mm to 7mm

6.Normal Operation Temperature:-50℃--800℃

7.Normal Operation Velocity:20-35m/s

Specifications

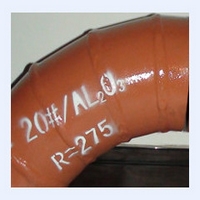

- SHS ceramic lined pipe

- Ceramic (Corundum: a-Al2O3) lined abrasion resistant straight pipe and Fittings are lined with highly abrasion resistant ceramic by SHS -------Self-propagating High-temperature Synthetic process.

- The composite pipe is composed of three layers: ceramic, intermediate, and steel layers. The ceramic layer is formed by molten alumina at a temperature above 2500 degree. The molten alumina produced from the reaction Fe2O3+2Al=2Fe+Al2O3 spreads on the inside wall of the steel pipe under the influence of a centrifugal force, then solidifies, so the ceramic layer has high density and smooth surface and bonds to the steel pipe.They are widely used to convey highly abrasive material such as fly ash and any other fine powder material in mine, thermo power generating, coal processing plant, matellurgy,construction,etc. The service life is 10 to 20 times longer than normal steel pipe.

- Features and Advantages

- Low friction factor of Ceramic at low impingement angles decreases the abrasion of materials maximally.

- Ceramic-lined composite steel pipe can take place of expensive stainless steel, nickel, cast stone or alloy pipes.And extended service life can also reduce maintenance cost.

- Preventing operation cease caused by frequent replacement of pipes and elbows .

- Excellent thermal resistance and abrasion resistance by ceramic material processing.

- Distinguished adhesive strength by high-temperature bonding agent.

- 10~20 times longer life span than products processed with SS, etc.

- No substance intermixed by abrasion during transportation.

- Low density makes it easy to carry and install.

- Features of Alumina Ceramic

- Alumina is a cost effective and widely used material in the family of engineered ceramics. Alumina ceramics have been developed and optimized for maximum wear resistance and corrosion resistance. A high density, diamond like hardness,fine grain structure and superior mechanical strength are the unique properties that make it the material of choice for a wide range of demanding applications.Ceramic has uses similar to Cast Basalt but it has greater resistance to wear in high velocity applications and impact resistance in extreme dynamic systems .

Main Products

ceramic lined pipe ,abrasion resistant pipe,concrete pump parts