abrasion resistant ceramic lined pipe

1.When abrasive material is transported through piping, either as pumped slurry or via pneumatic conveyance, the effect on the inner surface is devastating. The abrasive material quickly erodes the pipe from the inside out, which in more extreme cases can result in pipe leaks and even failure, or significant maintenance costs and downtime for pipe replacement.

2.For industries that regularly transport abrasive material, such as mining, power generation, pulp and paper, food, wastewater, cement, and steel industries, mild steel piping systems are simply not tough enough to stand up to the beating for more than a couple of years.

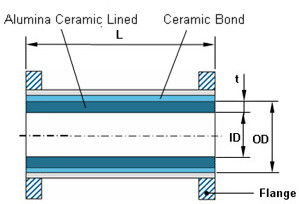

3.Pipes that we manufacture are designed with abrasion resistant ceramic linings. These ceramic lined pipes are rich with qualities like hardness, low sliding friction and resistance to high temperatures thus making it suitable component that can be effectively applied in coal bunkers, ash removal piping, sinter ash bunker and other related industrial machines.

1.Size :76mm-1020mm

2.Wall Thickness:9mm-27mm

3.Outside Housing Material:Carbon Steel Seamless Pipe

4.Inner Material:Alumina Ceramic

5.Ceramic Lining Thickness(Including Transition Layer): 3mm to 7mm

6.Normal Operation Temperature:-50℃--800℃

7.Normal Operation Velocity: 20-35m/s

Applications:

1.Paper Making: For conveying pulp.

2.Metal Mines: For conveying tailings, concentrates and backfill minerals.

3.Coal Preparation Plants: For conveying dense media, mixture and coal slurry.

4.Shipping: For clearing shipping channels and sediment transportation.

5.Power Plants: For deashing, deslagging, coal dropping, powder transportation and reclaimed powder systems.

Advantages:

1. Lower Cost than the Cast Iron Pipe and Alloy Steel Pipe

2.Low Density , Low Weight and Convenient Installation

3.Unique Abrasion and Impact Resistant

4.Excellent Corrosion Resistant

5.Smooth Inner Wall

2.For industries that regularly transport abrasive material, such as mining, power generation, pulp and paper, food, wastewater, cement, and steel industries, mild steel piping systems are simply not tough enough to stand up to the beating for more than a couple of years.

3.Pipes that we manufacture are designed with abrasion resistant ceramic linings. These ceramic lined pipes are rich with qualities like hardness, low sliding friction and resistance to high temperatures thus making it suitable component that can be effectively applied in coal bunkers, ash removal piping, sinter ash bunker and other related industrial machines.

1.Size :76mm-1020mm

2.Wall Thickness:9mm-27mm

3.Outside Housing Material:Carbon Steel Seamless Pipe

4.Inner Material:Alumina Ceramic

5.Ceramic Lining Thickness(Including Transition Layer): 3mm to 7mm

6.Normal Operation Temperature:-50℃--800℃

7.Normal Operation Velocity: 20-35m/s

Applications:

1.Paper Making: For conveying pulp.

2.Metal Mines: For conveying tailings, concentrates and backfill minerals.

3.Coal Preparation Plants: For conveying dense media, mixture and coal slurry.

4.Shipping: For clearing shipping channels and sediment transportation.

5.Power Plants: For deashing, deslagging, coal dropping, powder transportation and reclaimed powder systems.

Advantages:

1. Lower Cost than the Cast Iron Pipe and Alloy Steel Pipe

2.Low Density , Low Weight and Convenient Installation

3.Unique Abrasion and Impact Resistant

4.Excellent Corrosion Resistant

5.Smooth Inner Wall

Main Products

ceramic lined pipe ,abrasion resistant pipe,concrete pump parts