During molten aluminium processes,it is often a necessity to filter the metal to remove impurities,inclusions and dross prior to casting.The theory of filter is based on the process requirement of casting model, it can not only control molten Al. liquid’s velocity,flow,and temperature,but assist to remove impurities as well.The filter cloth range of products consists of woven glass fabrics coated with either phenolic resin or fine ceramic slurry to ensure that the product maintains its integrity during use.

There are many weave styles and facture shapes to choose from. The most common one are:

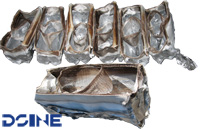

1.Combo bags

Control metal's flowrate, change its flow direction and with the filter function combined bag, also called “combag”It has complex structure of this combination bag. This bag can filtrate the molten metal that is being poured through a spout, and to distribute it all over the mold surface. It consists of a rectangular box with an open top made of an open-weave glass fiber fabric. The size of the openings of the fabric can vary depending on the weave construction and the type of yarns used.

This open fabric bottom controls the distribution, the spread and the speed of metal around the mold and finally control aluminium flowrate send to crystallizer in order to get the best temperature profile, reduce turbulence, prevent oxides.

2.Filter Socks

Filter the metal to remove impurities, inclusions and dross prior to casting. It has the good performance of high temperature resistance, thanks to the protection antioxidation coat.

It has the excellent representation of corrosion resistance, non melt, non-combustion, non smoke and odor and ensure to maintains its integrity

It is applicable for filtering the metal before trough and pouring ladle.

Eliminating the air bubble, ash oxides and other harmful impurities of Alu. liquid effectively.Do not affect alloy’s component, ensure the quality of aluminium casting.Sufficient stiffness to ensure an even molten metal flow.

Good chemical resistance to the molten metal, especially molten aluminum and high magnesium alloys.

Smokeless and odor at molten metal temperature and a non-expensive cost.It apply for manufacture enterprises of aluminium hub, aluminium piston,bar, ingot, board and all kinds of alloy accessories

3.Filtration Fabrics

It is often a necessity to filter the metal to remove impurities, inclusions and dross during molten aluminium production processes. The filter cloth consists of woven glass fabrics coated with ceramic to ensure its integrity during use. It is important to consider the production process when selecting your fabric style.

There are many weave styles and facture shapes to choose from. The most common one are:

1.Combo bags

Control metal's flowrate, change its flow direction and with the filter function combined bag, also called “combag”It has complex structure of this combination bag. This bag can filtrate the molten metal that is being poured through a spout, and to distribute it all over the mold surface. It consists of a rectangular box with an open top made of an open-weave glass fiber fabric. The size of the openings of the fabric can vary depending on the weave construction and the type of yarns used.

This open fabric bottom controls the distribution, the spread and the speed of metal around the mold and finally control aluminium flowrate send to crystallizer in order to get the best temperature profile, reduce turbulence, prevent oxides.

2.Filter Socks

Filter the metal to remove impurities, inclusions and dross prior to casting. It has the good performance of high temperature resistance, thanks to the protection antioxidation coat.

It has the excellent representation of corrosion resistance, non melt, non-combustion, non smoke and odor and ensure to maintains its integrity

It is applicable for filtering the metal before trough and pouring ladle.

Eliminating the air bubble, ash oxides and other harmful impurities of Alu. liquid effectively.Do not affect alloy’s component, ensure the quality of aluminium casting.Sufficient stiffness to ensure an even molten metal flow.

Good chemical resistance to the molten metal, especially molten aluminum and high magnesium alloys.

Smokeless and odor at molten metal temperature and a non-expensive cost.It apply for manufacture enterprises of aluminium hub, aluminium piston,bar, ingot, board and all kinds of alloy accessories

3.Filtration Fabrics

It is often a necessity to filter the metal to remove impurities, inclusions and dross during molten aluminium production processes. The filter cloth consists of woven glass fabrics coated with ceramic to ensure its integrity during use. It is important to consider the production process when selecting your fabric style.

Main Products

Combo Bags & Filter Socks,Foam Ceramic Filter ,boric oxide paint ,Grap