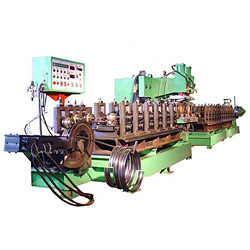

Motorcycle Rim Forming Machines

Description :

1. Full automatic Forming for Motorcycle Rim from material feeding until rim cutting.

2. Application for A-type (big wheel-spoke/nipple type)

motorcycle rim (OD) 16" - 18" x 45w~70w x (t.)1.2mm~1.83mm.

3. 2 models : Separated 18 forming roller sets Quick-change-mold 19 forming roller sets.

Specification :

1. Forming speed: 3 pcs/per min.

2. Forming roller section: 19 section (front 13/ rear 6).

3. For rim range: 16" - 18" x 45w - 70w.

4. Size of steel sheet: (w)100 - 130mm x (t)1.2 - 1.83mm.

5. Transmission motor: 10hp-front/7.5hp-rear.

6. Power source: 3Φ 380/440v 50/60hz.

7. Control power: 1Φ 220v 50/60hz.

8. Main power wiring: 38mm2.

9. Pneumatic air intake pipe: Φ1/2".

Description :

1. Full automatic Forming for Motorcycle Rim from material feeding until rim cutting.

2. Application for A-type (big wheel-spoke/nipple type)

motorcycle rim (OD) 16" - 18" x 45w~70w x (t.)1.2mm~1.83mm.

3. 2 models : Separated 18 forming roller sets Quick-change-mold 19 forming roller sets.

Specification :

1. Forming speed: 3 pcs/per min.

2. Forming roller section: 19 section (front 13/ rear 6).

3. For rim range: 16" - 18" x 45w - 70w.

4. Size of steel sheet: (w)100 - 130mm x (t)1.2 - 1.83mm.

5. Transmission motor: 10hp-front/7.5hp-rear.

6. Power source: 3Φ 380/440v 50/60hz.

7. Control power: 1Φ 220v 50/60hz.

8. Main power wiring: 38mm2.

9. Pneumatic air intake pipe: Φ1/2".

Main Products

welding machine, spot welding, seam welding, special machine