ⅠBrief intruduction :

Particular storage and discription material system insure the feeding accuracy and avoiding the effect of exterior material. So the products have high density.

Adopting synchronization vibration insures the products making average. The frequency can change according to different technics. Low frequency in feeding material, high frequency vibration makes the different material to have a optimal vibration way.

The computer is of fault diagnosis system. Warning signal is propitious to eliminate the fault. Combine with long-distance controlling system, it can achieve scrutiny, controlling, diagnosis.

ⅡControl system:

PLC intelligent control. Man-machine interface, control system equipped with complete logic control, production program, malfunction diagnosis system and remote control function. So it doesn’t need a professional person but only need a simple trainning to the operator.

Product scope:

It produces various bricks/blocks including color-face bricks (layered material feeding),through-body tiles,lock linkage blocks, road curb bricks, hydraulic blocks、hollow blocks, perforated bricks, and standard bricks etc.

Ⅲ Main Technical Specifications

Main Technical Specifications

Overall Dimension 9350×2320×2950(mm)

Rated pressure 21MPa

Main vibration form Platform vibration

Cycle Time 15-25 seconds

Vibrating Frequency 2800-4500 rolls/minute

Motors Power 44.58KW

Pallet Size 1100*900(mm)

Raw Materials crushed stone, sand, cement, dust and coal fly ash, cinder, slag, gangue, gravel, perlite, and other industrial wastes.

Applied Products concrete blocks, solid/hollow/cellular masonry products, paving stones with or without face mix, garden and landscaping products, slabs, edgers, kerbstones, grass blocks, slope blocks, interlocking blocks, etc.

ⅣProductivity of QT10-15 block making machine

Size Size mm Cycle

moulding QTY

/Mould Per hour Per day

Hollow brick

400*200*200

16-20s

10

1800pcs

18000pcs

400*150*200

15-20s

14

2520pcs

67200pcs

Color brick

225*112.5*60

15-17s

28

6720pcs

12480pcs

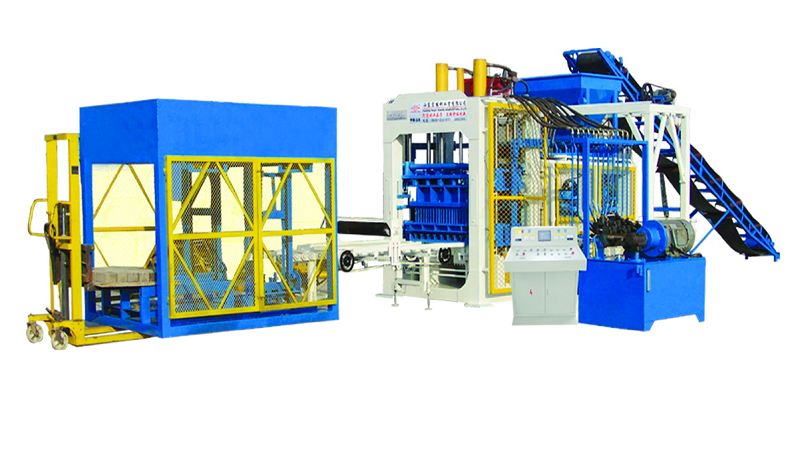

Ⅴ Equipment photos

Item Model Unit

Host machine QT10-15

PLC control system

Mould 1100*900mm

Stacker For QT10-15

Compulsive mixer JS750

Belt conveyor 8m

Batching machine PLD 1200

Cement silo 100T

Screw conveyor 9m / Ø 219mm

Plastic Pallet 1100*900*30mm

.

Ⅵ Installation service:

My company could send one or two of our engineers to buyers place to direct the installation and give the operation training. The customers should pay for the cost of room and board, and the round-trip tickets for our engineers.

Suggestion of the engineer:

The Hydraumatic system of this machine is unique.

First,the vibration box was drive by the Hydraumatic motor,not the electrical engine,so the exciting power is more bigger than the machine drive by the electrical engine.The compactedness of its production is more well than the machine drive by the electrical engine.

Second,the Up-mould hydro-cylinder include 2 thick and 1 thin.When the up mould mores,it was controlled by the thin one,the thin one makes it moves fast for Principle of Hydraulics,so the Molding cycle of this machine will be short.And when the up-mould pressure the raw material,it was controlled by the 2 thick hydro-cylinder,who give the raw material more bigger pressure than the thick one.So the compactedness of the production is more well.

2.The material add system is unique.

The unigque forcing material-feeding system with a specialized iron bar adjust to different mould cases,also it will make the raw material secondly mixing,and add it to the gap of the mould.It will be very good to the thin-wall hollow brick.

3.The vibration system is unique.

For the vibration system is drive by the motor not the engine,it is easy to change the vibration

Particular storage and discription material system insure the feeding accuracy and avoiding the effect of exterior material. So the products have high density.

Adopting synchronization vibration insures the products making average. The frequency can change according to different technics. Low frequency in feeding material, high frequency vibration makes the different material to have a optimal vibration way.

The computer is of fault diagnosis system. Warning signal is propitious to eliminate the fault. Combine with long-distance controlling system, it can achieve scrutiny, controlling, diagnosis.

ⅡControl system:

PLC intelligent control. Man-machine interface, control system equipped with complete logic control, production program, malfunction diagnosis system and remote control function. So it doesn’t need a professional person but only need a simple trainning to the operator.

Product scope:

It produces various bricks/blocks including color-face bricks (layered material feeding),through-body tiles,lock linkage blocks, road curb bricks, hydraulic blocks、hollow blocks, perforated bricks, and standard bricks etc.

Ⅲ Main Technical Specifications

Main Technical Specifications

Overall Dimension 9350×2320×2950(mm)

Rated pressure 21MPa

Main vibration form Platform vibration

Cycle Time 15-25 seconds

Vibrating Frequency 2800-4500 rolls/minute

Motors Power 44.58KW

Pallet Size 1100*900(mm)

Raw Materials crushed stone, sand, cement, dust and coal fly ash, cinder, slag, gangue, gravel, perlite, and other industrial wastes.

Applied Products concrete blocks, solid/hollow/cellular masonry products, paving stones with or without face mix, garden and landscaping products, slabs, edgers, kerbstones, grass blocks, slope blocks, interlocking blocks, etc.

ⅣProductivity of QT10-15 block making machine

Size Size mm Cycle

moulding QTY

/Mould Per hour Per day

Hollow brick

400*200*200

16-20s

10

1800pcs

18000pcs

400*150*200

15-20s

14

2520pcs

67200pcs

Color brick

225*112.5*60

15-17s

28

6720pcs

12480pcs

Ⅴ Equipment photos

Item Model Unit

Host machine QT10-15

PLC control system

Mould 1100*900mm

Stacker For QT10-15

Compulsive mixer JS750

Belt conveyor 8m

Batching machine PLD 1200

Cement silo 100T

Screw conveyor 9m / Ø 219mm

Plastic Pallet 1100*900*30mm

.

Ⅵ Installation service:

My company could send one or two of our engineers to buyers place to direct the installation and give the operation training. The customers should pay for the cost of room and board, and the round-trip tickets for our engineers.

Suggestion of the engineer:

The Hydraumatic system of this machine is unique.

First,the vibration box was drive by the Hydraumatic motor,not the electrical engine,so the exciting power is more bigger than the machine drive by the electrical engine.The compactedness of its production is more well than the machine drive by the electrical engine.

Second,the Up-mould hydro-cylinder include 2 thick and 1 thin.When the up mould mores,it was controlled by the thin one,the thin one makes it moves fast for Principle of Hydraulics,so the Molding cycle of this machine will be short.And when the up-mould pressure the raw material,it was controlled by the 2 thick hydro-cylinder,who give the raw material more bigger pressure than the thick one.So the compactedness of the production is more well.

2.The material add system is unique.

The unigque forcing material-feeding system with a specialized iron bar adjust to different mould cases,also it will make the raw material secondly mixing,and add it to the gap of the mould.It will be very good to the thin-wall hollow brick.

3.The vibration system is unique.

For the vibration system is drive by the motor not the engine,it is easy to change the vibration

Certificate

- get the certification of ISO9001/CE/SGS

Main Products

block making machine.pipe making machine, concrete batching plant AAC