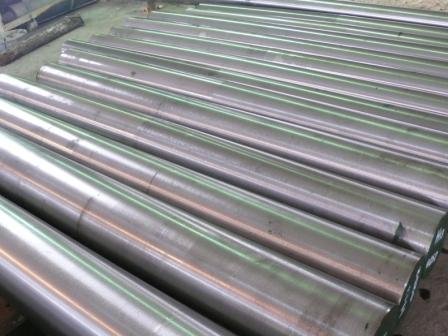

Tool Steel D6, 1.2436, Cr12W

tool steel/die steel/mould steel1.2436, Cr12W, D6

tool steel, die steel, mould steel, steel, cold steel, hot steel, alloy steel, 1.2436,Cr12W,D6

quantity 3000 m/t per month, MOQ:10 m/t,

Payment: L/C,T/T

EAF+LF+VD,forging,anneal

Scale

Forged round 50~380mm ,Forging Plate 20~200*40~410

Application

Impression pressure and Cold cutting blade and so on

Die tensile impact load smaller

Factory state

Annealing HB

Standard Gb/T1299-2000 C2.00/2.30 Mn

High-carbon and high-chromium

Tool steel,high hardenability,less quenching distortion,

high hardness,good abrasion resistance

heat treatment

quenching 950 ~ 980oc oil (need twice warm to cold 500oc ~ 850oc ) hrc >/= 60 eliminate stress and stability back to the address 180 ~ 200oc >/=2 hours hrc >/= 60 and 62 if necessary, 320 ~ 350oc >/= two hours to go back to the fire, 58 hrc >/= ~ annealing , 780 ~ 800oc got cold

tool steel, die steel, mould steel, steel, cold steel, hot steel, alloy steel, 1.2436,Cr12W,D6

quantity 3000 m/t per month, MOQ:10 m/t,

Payment: L/C,T/T

EAF+LF+VD,forging,anneal

Scale

Forged round 50~380mm ,Forging Plate 20~200*40~410

Application

Impression pressure and Cold cutting blade and so on

Die tensile impact load smaller

Factory state

Annealing HB

Standard Gb/T1299-2000 C2.00/2.30 Mn

High-carbon and high-chromium

Tool steel,high hardenability,less quenching distortion,

high hardness,good abrasion resistance

heat treatment

quenching 950 ~ 980oc oil (need twice warm to cold 500oc ~ 850oc ) hrc >/= 60 eliminate stress and stability back to the address 180 ~ 200oc >/=2 hours hrc >/= 60 and 62 if necessary, 320 ~ 350oc >/= two hours to go back to the fire, 58 hrc >/= ~ annealing , 780 ~ 800oc got cold

Main Products

tool steel,die steel,mould steel,alloy tool steel,special steel