Executive Standard : API Spec 5CT (ISO 11960:2004) CASING AND TUBING :API (American Petroleum Institute)

Product particular communication:

1) Size: 6.35 - 127 mm (OD) x 0.89 - 15mm (WT) ;

2) Tight tolerance, Smooth surface, Uniform mechanical property(Mechanical Properties equilibrium) ;

3) Heat treatment: BK, BKS, GBK, NBK,Stress Relief, Normalizing, Spheroidize Anneal, Annealing, Bright Annealing, Normalized, Quenched and Tempered, Solution Annealing, etc ;

4) Continuous stenciling as required ;

5) Rust prevention treatment, such as: immersion oil, lacquer, passivation, phosphating,etc;

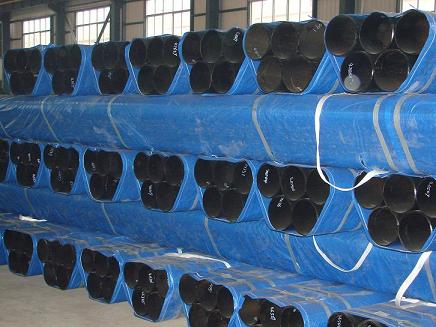

6) Plastic plugs or caps on both ends as required ;

7) Packing Type: Round , Square, Rectangle, Hexagon. Streamline, etc.

8) Relevant Test: Chemical Component Analysis,Mechanical Properties(Ultimate tensile strength,Yield strength,Elongation),Technics Properties(Flattening Test,Flaring Test,Bending Test,Hardness Test,Blow Test,etc), Exterior Size Inspection, Nondestructive Test,Hydrostatic Test;

9) Main Applications: Automobile and Bearing Industry, Mechanical and Structral Purpose, Hydraulic and Petrochemical Purpose, etc

Commercial Information:

1) Delivery :On time ;

2) Min Order : 2 Tons; However, ERW and DOM Tube need 100 T Per Item ;

3) Packing way : As per our export standard for shipment ;

4) Term of payment : 30% T/T within 3 days after signing the contract, balance 70% before shipment. Or 30%T/T +70% irrepealable L/C ;

5) Delivery Port : Shanghai Port ;

6) Offer Validity : 5-7 Days ;

7) Container : 20' or 40', etc ;

8) Manufacture methods : Cold Finished and Hot Finished.

Product particular communication:

1) Size: 6.35 - 127 mm (OD) x 0.89 - 15mm (WT) ;

2) Tight tolerance, Smooth surface, Uniform mechanical property(Mechanical Properties equilibrium) ;

3) Heat treatment: BK, BKS, GBK, NBK,Stress Relief, Normalizing, Spheroidize Anneal, Annealing, Bright Annealing, Normalized, Quenched and Tempered, Solution Annealing, etc ;

4) Continuous stenciling as required ;

5) Rust prevention treatment, such as: immersion oil, lacquer, passivation, phosphating,etc;

6) Plastic plugs or caps on both ends as required ;

7) Packing Type: Round , Square, Rectangle, Hexagon. Streamline, etc.

8) Relevant Test: Chemical Component Analysis,Mechanical Properties(Ultimate tensile strength,Yield strength,Elongation),Technics Properties(Flattening Test,Flaring Test,Bending Test,Hardness Test,Blow Test,etc), Exterior Size Inspection, Nondestructive Test,Hydrostatic Test;

9) Main Applications: Automobile and Bearing Industry, Mechanical and Structral Purpose, Hydraulic and Petrochemical Purpose, etc

Commercial Information:

1) Delivery :On time ;

2) Min Order : 2 Tons; However, ERW and DOM Tube need 100 T Per Item ;

3) Packing way : As per our export standard for shipment ;

4) Term of payment : 30% T/T within 3 days after signing the contract, balance 70% before shipment. Or 30%T/T +70% irrepealable L/C ;

5) Delivery Port : Shanghai Port ;

6) Offer Validity : 5-7 Days ;

7) Container : 20' or 40', etc ;

8) Manufacture methods : Cold Finished and Hot Finished.

Features

- ASTM Seamless Alloy Boiler Tube

- Product Names : Tube For API .

- Product particular communication:

- 1) Size: 6.35 - 406 mm (OD) x 0.89 - 35mm (WT) ;

- 2) Tight tolerance, Smooth surface, Uniform mechanical property(Mechanical Properties equilibrium) ;

- SAE Seamless Steel Tube for Car

- roduct particular communication:

- 1) Size: 6.35 - 406 mm (OD) x 0.89 - 35mm (WT) ;

- 2) Tight tolerance, Smooth surface, Uniform mechanical property(Mechanical Properties equilibrium) ;

- 3) Heat treatment: BK, BKS, GBK, NBK,Stress Relief, Normalizing, Spheroidize Anneal, Annealing, Bright Annealing, Normalized, Quenched and Tempered, Solution Annealing, etc ;

Main Products

seamless steel tube, seamless steel pipe, alloy tube, alloy tube