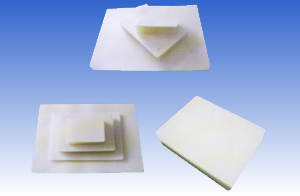

Most thermal laminating film consists of two layers: a base layer of polyester and an adhesive layer of polyethylene. The polyester layer forms the harder outer surface of the film and does not melt at laminating temperature. It provies rigidity and protection for your laminated items. The greater the polyester content, the higher the level of protection, rigidity and luster. The polyethylene layer melts at laminating temperature and bonds the film onto the subject material under the pressure of the laminating rollers. As and X-test demonstrates, the adhesive is pressed into the paper and fills irregularities in the surface.

Features

- 1. Anti-static electricity;

- 1. Anti-static electricity;

- 2. Adhesive emtremely;

- 3. Low temperature needed (aprox. 110º C-135º C);

- 4. Width range: 54mm-1300mm;

- 5. Thickness range: 32Mic-250Mic;

- 6. Finish: glossy

- 2. Adhesive emtremely;

- 3. Low temperature needed (aprox. 1

- 4. Width range: 54mm-1300mm;

- 5. Thickness range: 32Mic-250Mic;