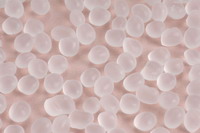

Translucent material with excellent tensile strenth and compression set. Scratch resistance. RoHS compliant. FDA certified. Free of phthalate, PAHS and nonylphenol. Suitable for airbag cover, medical tube, tools grip, syringe stopper,, medical wheel, and gasket

Specifications

- PHOENIX 02 SERIES

- Scratch resistance. Good physical properties.

- Overmold to polypropylene.

- PHOENIX 03 SERIES

- Scratch resistance. Very excellent tear and tensile strength. Suitable for syringe stopper, seal, packing. Overmold to polypropylene.

- PHOENIX 04 SERIES

- Scratch resistance. Very excellent tear and tensile strength. Low melt flow index. Suitable for extrusion applications like cable and wire sheath.

Features

- Scratch resistance

- No white scratch

- Excellent properties

- Excellent tensile strength and compression set. Very good elongation and tear strength. Suitable for high performance applications

- Easy to process and color

- Without vulcanization. It can be applied with standard plastic process like injection molding, extrusion or blow molding. Easy to color with pigment or masterbatches.

- Lightweight

- Density around 0.88

- Excellent brittle temperature

- At -50~ -60 Celsius, it can still remain flexible and no stiffness.