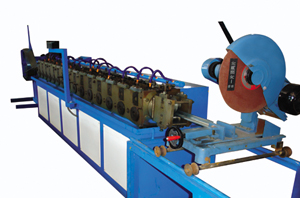

TDC unit is one of the two universal flange making systems in the world. It can save time and material drastically with its well-seal, strong and durable joint structure. So it is especially suitable for producing a duct with a large sectional area. Today many famous buildings in the world utilize this kind of structure in the ventilation system such as the American Kennedy Space Center, and Guangzhou CITIC Plaza. The unit consists of a feeding frame, main forming machine and a shearing unit, which includes grinder and hydraulic shearing unit. The hydraulic shearing unit makes fixed cutting available with very little burr, and may be operated automatically with a maximum work speed of 6 m/min. It is divided into four types: T-20, T-30, T-35, and T-40 with their corresponding duct corner T-20DC, T-30DC and T-40DC. TDC made by SBKJ may match and produce all the ducts in the DW144 standard, and has passed the HVAC PW/TMI (1987) pressure test, which is a specialty test for the intensity and sealed condition of a duct.

Specifications

- main techology

- Model SBT-20 SBT-30 SBT-40 SBT-35

- Weight (kg) 2500 2500 2500 3000

- Capacity(mm) 0.6-0.8 1.0 1.0-1.2 1.0

- Motor(kw) 2.2/2.2 . 2.2/2.2 2.2/2.2 2.2/2.2

- Size(mm) 3650x700x1500 3650x700x1500 3650x700x1500 3650x700x1500

Features

- TDC FABRICATION AND INSTALLATION

- TDC FABRICATION AND INSTALLATION

- TDC angle - flanged joints requires a ordinary circular saw cut for cutting. Cut two lengths of the flanges 30mm shorter than duct overall dimension. The flanges should be cut in the direction shown to prevent metal cutting damage on the Cut flanges. If any burring has occurred during cutting of the flange, this must be removed before assembly.

- Insert four corners joints into the end of the flange. Please note. Ensure the corners are fully inserted into the flange. Complete the whole frame by securing the corner.

- The frame to the duct, should be fairly tapped when inserting from one side of the frame and then along the full length of the flange.

- Fixing the flange into the duct by various methods, spot welding or riveting. Spacing for fastening to be as DW144 Table 5. Maximum distance from the corners should not exceed 50mm.

- When the frame is securely fixed, it is suggested that a duct sealant needs to be applied, on either the inside or outside of the flange and on the corner piece where it meets the duct.

Main Products

spiral tube former machine ,TDC/TDF flange former machine