high broken ratio, reliable operation, simple structure

Our crushers are new products designed by our company after absorbing the advanced technology home and abroad, which can deal with various materials including granite, limestone, basalt, bank gravel,etc. It particle size is not more than 500mm and the compressive resistance is not more than 360 Mpa. These crushers have features of high broken ratio, high efficiency, energy-saving, convenient maintenance, reliablie performance, etc. The crushed materials are cube shaped, and the size of discharging is adjustable, so this kind of crusher is widely used in mining, road, railway, artificial gravel, building material and other industries.

Specifications

- Jaw crusher

- The jaw crusher has a feature of big crushing ratio, uniform finished

- product size, simple structure, reliable operation, easy maintenance,

- low operation cost. It is widely used in mining, metallurgy, building

- material, highway ,railway, irrigation works and chemical industries

- for crushing various materials with cold compression strength no more than

- 350Mpa. It is preferred equipment for the complete set of product line

- as the first step crusher.

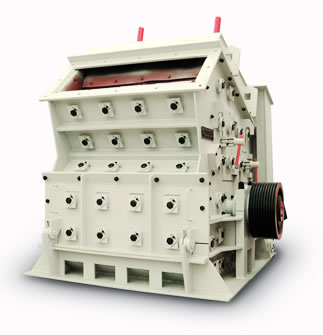

- Impact crusher

- The jaw crusher has a feature of big crushing ratio, uniform finished

- product size, simple structure, reliable operation, easy maintenance,

- low operation cost. It is widely used in mining, metallurgy, building

- material, highway ,railway, irrigation works and chemical industries

- for crushing various materials with cold compression strength no more than

- 350Mpa. It is preferred equipment for the complete set of product line

- as the first step crusher.

- Hammer crusher

- The hammer crusher (hammer mill) crushes by the collicions between high-speed hammer and materials, high reduction ration, high efficiency, etc. The PC hammer crusher (hammer mill) were developed for both dry and wet crushing of brittle, medium-hard materials for the mining, cement, coal, metallurgic, construction material, road building, and as well as water and electricity industries.

- Impact fine crusher

- The impact fine crusher has many advantages, such as simple structure, reliable working condition and convenient repair, which is widely used for mine, cement, sand-making brick and tile industry. Paticularlly applicable to the preparation of the brick and the industry.

- Double jaws crusher

- The impact fine crusher has many advantages, such as simple structure, reliable working condition and convenient repair, which is widely used for mine, cement, sand-making brick and tile industry. Paticularlly applicable to the preparation of the brick and the industry.

Features

- Jaw crusher

- The jaw crusher has a feature of big crushing ratio, uniform finished

- product size, simple structure, reliable operation, easy maintenance,

- low operation cost. It is widely used in mining, metallurgy, building

- material, highway ,railway, irrigation works and chemical industries

- for crushing various materials with cold compression strength no more than

- 350Mpa. It is preferred equipment for the complete set of product line

- as the first step crusher.

- Model Size of feeder opening (mm) Max inlet size (mm) Adjusting range of discharge (mm) Capacity (t/h) Spindle speed (r/min) Motor power (kw)

- PE250×400 250×400 210 20-60 5-20 300 15

- PE400×600 400×600 340 40-100 15-60 275 30

- PE500×750 500×750 425 50-100 45-80 275 55

- PE550×750 550×750 450 50-120 45-100 275 55

- PE600×900 600×900 500 65-160 50-120 250 55-75

- PE620×900 620×900 520 85-145 50-128 250 55-75

- PE670×900 670×900 570 135-195 60-140 250 55-75

- Impact crusher

- Description:

- This series of Impact Crusher are new products designed by our company after absorbing the advanced technology home and abroad, which can deal with various materials including granite, limestone, basalt, bank gravel,etc. It particle size is not more than 500mm and the compressive resistance is not more than 360 Mpa. These crushers have features of high broken ratio, high efficiency, energy-saving, convenient maintenance, reliablie performance, etc. The crushed materials are cube shaped, and the size of discharging is adjustable, so this kind of crusher is widely used in mining, road, railway, artificial gravel, building material and other industries.

- Techical Data:

- Model Size

- (mm) Size of feeder opening

- (mm) Max feeding size

- (mm) Capacity

- (t∕h) Motor power

- (t∕h)

- PF—0607 Ф―644×740 320×770 100 10―20 30

- PF—0807 Ф―850×700 400×730 300 15―30 30―45

- PF—1008 Ф―1000×800 400×830 300 30―50 37―55

- PF—1010 Ф―1000×1050 400×1080 350 50―80 55―75

- PF—1210 Ф―1250×1050 400×1080 350 70―120 110―132

- PF—1212 Ф―1250×1250 400×1300 350 100―150 132―160

- PF—1214 Ф―1250×1400 400×1430 400 130―180 160―200

- PF—1315 Ф―1320×1500 860×1520 500 160―250 180―260

- PF—1320 Ф―1320×2000 860×2030 500 300―350 300―375

- Hammer crusher

- The hammer crusher (hammer mill) crushes by the collicions between high-speed hammer and materials, high reduction ration, high efficiency, etc. The PC hammer crusher (hammer mill) were developed for both dry and wet crushing of brittle, medium-hard materials for the mining, cement, coal, metallurgic, construction material, road building, and as well as water and electricity industries.

- Model Parameters PC66 PC68 PC810 PC1010 PC1012 PC1215 PC1515 PC2020

- Rotor dia (mm) 600 800 1000 1000 1200 1500 1500 2000

- Intine width (mm) 600 600 800 1000 1000 1200 1500 2000

- Feeding size (mm) 200 300 400 400 400 400 400 500

- Opening size (mm) 20 20 20 20 20 20 20 20

- Capacity (t/h) 30-40 40-60 60-80 80-120 90-140 100-150 120-180 150-200

- Motor (kw) 37 55 75 75 110 132 132 220

- Model Parameters PS68 PS810 PS1010 PS1110 PS1012 PS1215 PS1515 PS2020

- Impact fine crusher

- The impact fine crusher has many advantages, such as simple structure, reliable working condition and convenient repair, which is widely used for mine, cement, sand-making brick and tile industry. Paticularlly applicable to the preparation of the brick and the industry.

- Model Size

- (mm) Size of feeder opening

- (mm) Max feeding size

- (mm) Capacity

- (t∕h) Motor power

- (t∕h)

- PF—0607 Ф―644×740 320×770 100 10―20 30

- PF—0807 Ф―850×700 400×730 300 15―30 30―45

- PF—1008 Ф―1000×800 400×830 300 30―50 37―55

- PF—1010 Ф―1000×1050 400×1080 350 50―80 55―75

- PF—1210 Ф―1250×1050 400×1080 350 70―120 110―132

- PF—1212 Ф―1250×1250 400×1300 350 100―150 132―160

- PF—1214 Ф―1250×1400 400×1430 400 130―180 160―200

- PF—1315 Ф―1320×1500 860×1520 500 160―250 180―260

- PF—1320 Ф―1320×2000 860×2030 500 300―350 300―375

- Double jaws crusher

- The impact fine crusher has many advantages, such as simple structure, reliable working condition and convenient repair, which is widely used for mine, cement, sand-making brick and tile industry. Paticularlly applicable to the preparation of the brick and the industry.

- Model Size

- (mm) Size of feeder opening

- (mm) Max feeding size

- (mm) Capacity

- (t∕h) Motor power

- (t∕h)

- PF—0607 Ф―644×740 320×770 100 10―20 30

- PF—0807 Ф―850×700 400×730 300 15―30 30―45

- PF—1008 Ф―1000×800 400×830 300 30―50 37―55

- PF—1010 Ф―1000×1050 400×1080 350 50―80 55―75

- PF—1210 Ф―1250×1050 400×1080 350 70―120 110―132

- PF—1212 Ф―1250×1250 400×1300 350 100―150 132―160

- PF—1214 Ф―1250×1400 400×1430 400 130―180 160―200

- PF—1315 Ф―1320×1500 860×1520 500 160―250 180―260

- PF—1320 Ф―1320×2000 860×2030 500 300―350 300―375

Certificate

- ISO:9001 ISO:2008

Main Products

crusher, vibrating screen