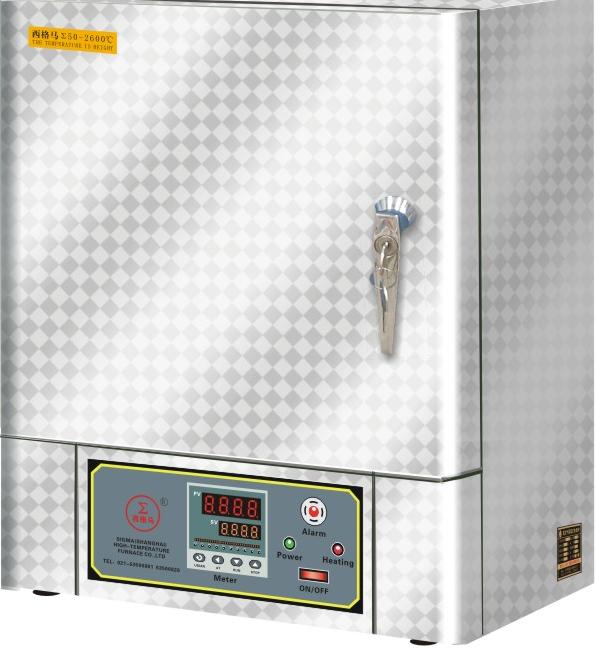

SHF series high temperature furnaces for laboratory are perfectly designed, which congregate many patents and are very safe, reliable, and practical.

1. Maximum temperature: 1000℃

2. Adopting vacuum molding technology, the heating wire is inlaid in the inside surface of the ceramic board and the chamber lining is once forming, preventing contamination by the volatile matter.

3. The heating wire is set in the four sidewalls inside the chamber. Adopting special insulating design,

4. Have double-layer housing. The heat is insulated by the circulating air, so the temperature of the outside surface is very low.

5. Moveable pulling block is set between the furnace body and the controller, which is convenient for putting the fire-screen door and sinter.

6. Designed of patent technique, the chamber is replaceable, and the user can adjust the position of the chamber freely. The door and the chamber of the furnace are perfectly sealed.

7. Have automatic power failure protective function once the door is open. Have over temperature alarm function. Have power failure function once the thermocouple is damaged. Have controlling function with the built-in parameter pass code.

8. Heating rate: 10-30℃/min. 30-segment automatically heating up programs

9. Provide RS-485 communication port and Sigma data management software, which can record the history data and the temperature rising curve, correct the temperature deviated error, and manage multi-equipments and remote failure analysis.

10. Multiple safety protective design. It’s very safe and durable.

11. Optional door: side opening door and parallel pulling door.

Extra option:

1. Observation hole: The changing process can be observed by the observation hole.

2. Exhaust chimney

3. Glass tube flow-meter, inlet pipe and outlet pipe

4. Set up and debugging, training

5. Spare parts

1. Maximum temperature: 1000℃

2. Adopting vacuum molding technology, the heating wire is inlaid in the inside surface of the ceramic board and the chamber lining is once forming, preventing contamination by the volatile matter.

3. The heating wire is set in the four sidewalls inside the chamber. Adopting special insulating design,

4. Have double-layer housing. The heat is insulated by the circulating air, so the temperature of the outside surface is very low.

5. Moveable pulling block is set between the furnace body and the controller, which is convenient for putting the fire-screen door and sinter.

6. Designed of patent technique, the chamber is replaceable, and the user can adjust the position of the chamber freely. The door and the chamber of the furnace are perfectly sealed.

7. Have automatic power failure protective function once the door is open. Have over temperature alarm function. Have power failure function once the thermocouple is damaged. Have controlling function with the built-in parameter pass code.

8. Heating rate: 10-30℃/min. 30-segment automatically heating up programs

9. Provide RS-485 communication port and Sigma data management software, which can record the history data and the temperature rising curve, correct the temperature deviated error, and manage multi-equipments and remote failure analysis.

10. Multiple safety protective design. It’s very safe and durable.

11. Optional door: side opening door and parallel pulling door.

Extra option:

1. Observation hole: The changing process can be observed by the observation hole.

2. Exhaust chimney

3. Glass tube flow-meter, inlet pipe and outlet pipe

4. Set up and debugging, training

5. Spare parts

Main Products

Chemicals Lab Supplies Laboratory Heating Equipments, Muffle Furna