1. Shot and ejection position : Digital setting.

2. High-speed toggle link mechanism design: Enhance productivity.

3. Hidden stroke guide design: Replace molds quickly and efficiently.

4. Memory storage for casting parameters: Up to 100 models.

5. Error message and historical records display.

6. The lubricant discharge is controlled by the cycle times of die opening and closing.

7. During injection, the pressure of the core could be opted to alter.

8. The number of cycles for providing plunger tip lubricant can be adjusted.

9. The order of sprayers and cores' operation can be set.

10. Automation setting : Shorten cycle time.

2. High-speed toggle link mechanism design: Enhance productivity.

3. Hidden stroke guide design: Replace molds quickly and efficiently.

4. Memory storage for casting parameters: Up to 100 models.

5. Error message and historical records display.

6. The lubricant discharge is controlled by the cycle times of die opening and closing.

7. During injection, the pressure of the core could be opted to alter.

8. The number of cycles for providing plunger tip lubricant can be adjusted.

9. The order of sprayers and cores' operation can be set.

10. Automation setting : Shorten cycle time.

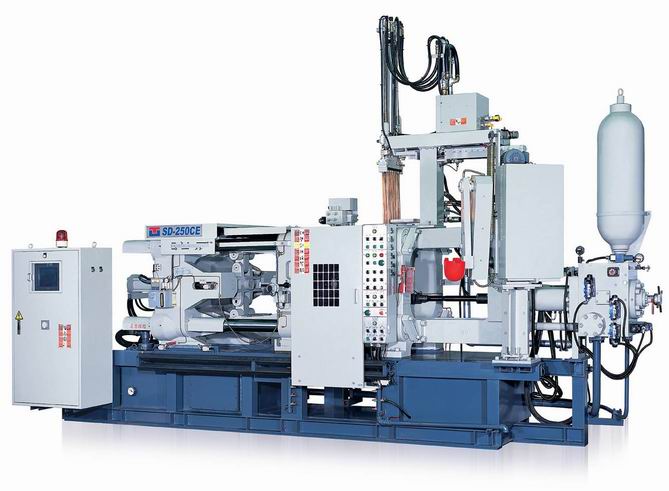

Specifications

- Auxiliaries

- automatic ladlers, automatic sprayers, automatic extractors, molten metal automatic charging systems, cold chamber die casting machines, solubled release agent dilutor, automatic auxiliary equipments, casting equipments, precision parts.

Features

- High quality and performance

- The first ISO9001 certificated professional manufacturer in Taiwan for automatic auxiliary equipments applied to die casting field.

Main Products

Cold chamber die casting machine