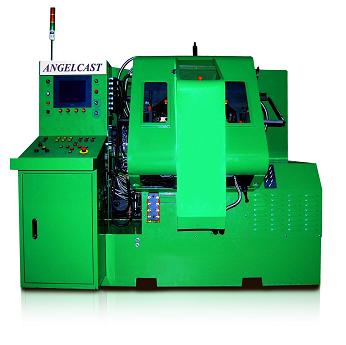

Angelcast multi slide die casting machine consists of 2-6 slides all moving independently and each with its own die blocks. When the die casting machine closes, the die blocks form a complete cavity to inject the material. Instead of feeding the cavity through a sprue and runner system, it is directly injected through the parting line, thus eliminating sprue and flash effects.

Specifications

- Die size

- 48x60mm

- 60x60mm

- 60x100mm

- 100x100mm

- 150x200mm

- Clamping force

- 8 tons

- 20 tons

- 45 tons

- Dry clycle speed

- 35/mins

- 25/mins

- 20/mins

- Melt rate

- 60kg/hr

- Furnance capacity

- 200kg

Features

- Multi-slide design

- Evolutionary multi-slide design, mold design diversity, wide selection of mold parting directions (2-6 directions), the core can be removed from any angle and direction, surpass traditional mold limitations, reduce secondary operations.

- High precision

- High mold precision (0.005mm), suitable for high precision and high complexity parts production. Standardized mold to reduce mold production cost.

- Parting-line injection

- Unique parting line die casting method, eliminates the need of sprue, as the result reduction in material over 50% and saving in labor and energy.

- High speed

- High speed production, superior production cycle, up to 35 shots per minute and easy die changeover in 15 minutes.

- High surface finish

- Fully hydraulic design, highly consistent parts quality, constant injection pressure, good parts density, and superior surface finish.

Certificate

- ISO9001:2000

- CE Marking

Main Products

Multi-slide die casting machine, multi-slide & conventional tooling