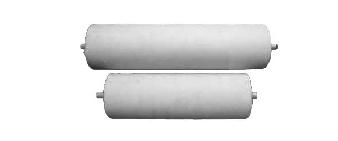

Aiming at solving the defects of the traditional steeliness rollers, such as when encountered acid, alkali and salt, they are easy to get corrosive, sticky, abrade, and due to getting stuck of the axletree, the belt is easy to lacerate as well as their short service life, etc. Our company has succeeded in developing wear-resistant ceramic rollers. After the terminal operating results in iron and steel, chemical, fertilizer, mining, power plant, salt works and shipside industries show that the products are not only of wear and acid and alkali salt resistance , anti-oxidation, operation stability, security features, but also can effectively prevent the belt deviation, reduce partial loss of belt, prolong its service life, reduce the manpower, material resources and time caused by replacing rollers frequently, lower operating costs and improve the efficiency of belt conveyor. As operating under harsh environment in the open air, their service life is 3-5 times longer than the traditional one.

Specifications

- Compressive strength

- Compressive strength: 145 Mpa

- Flexural strength

- Flexural strength: 80 ~ 120 Mpa

- Hardness

- Hardness (Mohs's) :more than 7

- Adaptable Temperature

- Adaptable Temperature: -80 degree to 180 degree

- Water absorption

- Water absorption: less than1%

Features

- Density

- Density: 2.8 g/cm3

- Abrasion Rate

- Abrasion Rate: less than1.0

- Service life of Ceramic roll

- Service life of Ceramic roll :more than 10 years

- Service Life of Axletree

- Service Life of Axletree: less than 3 years (about three years to replace the Axletrees)

Main Products

Conveyor Belt Vulcanizer, Water Cooling Conveyor Belt Vulcanizer, lo