Sieve bend screen is the solution to many de-watering, sizing, and wastewater cleanup problems. Typical uses are sewage treatment, laundry wash water clean-up, poultry, fish, fruit and vegetable wastewater processing, minerals processing, coal preparation, paper production, textile plants, and many more.

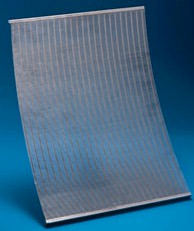

Sieve bend consists of a concave curved profile wire screen mounted in a frame with the screen openings perpendicular to the flow. A curved screen has greater capacity than a flat screen due to forces exerted as material flows against the curved surface.

Sieve bends are also known as DSM screens, after Dutch State Mines, who introduced the sieve bend as a static sizing screen having ten times greater capacity than conventional vibrating screens.

Larger particles continue down the screen surface, with much of the liquid removed. Separation size is considerably smaller than screen openings, usually about one half the opening sizes.

Sieve bend consists of a concave curved profile wire screen mounted in a frame with the screen openings perpendicular to the flow. A curved screen has greater capacity than a flat screen due to forces exerted as material flows against the curved surface.

Sieve bends are also known as DSM screens, after Dutch State Mines, who introduced the sieve bend as a static sizing screen having ten times greater capacity than conventional vibrating screens.

Larger particles continue down the screen surface, with much of the liquid removed. Separation size is considerably smaller than screen openings, usually about one half the opening sizes.

Main Products

wedge wire screen, water well screen, oil well screen, stainless steel