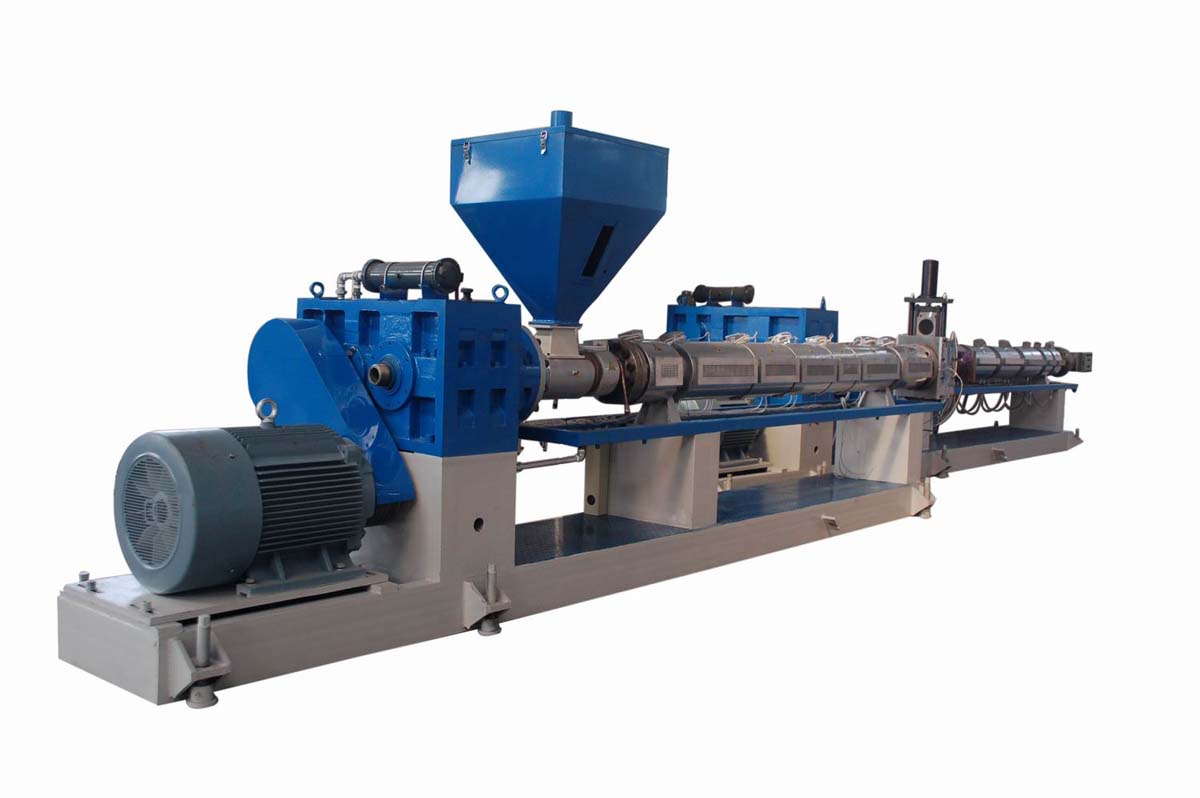

XPS insulation line

Model: PTS135-150-XF

Output: 300 - 350 kg/h or 180 - 200 m3/24h

Model: PTS150-200-XF

Output: 400 - 550 kg/h or 300 - 320 m3/24h

Product: Extruded polystyrene (XPS) foam board

Board width: 600 mm, 900mm, 1200mm after trimmed.

Board thickness: 20mm--100mm

Density: 30-40kg/ m3

Material: Polystyrene(PS)

Blowing agent: Freon(HFC,HCFC,CO2)

Standard configration

1 Mixing system

2 Feeding system

3 Primary extruder

4 Metering pump

5 Hydraulic screen changer

6 Secondary extruder

7 Slot die

8 Oil temperature controller

9 Board calibrator

10 First haul-off system

11 Take-off system

12 Cut-to-width system

13 Second haul-off system

14 Cut-to-length system

15 Electrical control equipment

* Margin recycle system (PTRECYCLERTM)

* Optional finishing machines

1 Embossing unit

2 Planer (Rough; Fine)

3 Groover (Straight; Dovetail)

4 Edge trimmer (SL; RC; TG)

5 Slice cutting machine

6 Aluminium foil composite machine

Model: PTS135-150-XF

Output: 300 - 350 kg/h or 180 - 200 m3/24h

Model: PTS150-200-XF

Output: 400 - 550 kg/h or 300 - 320 m3/24h

Product: Extruded polystyrene (XPS) foam board

Board width: 600 mm, 900mm, 1200mm after trimmed.

Board thickness: 20mm--100mm

Density: 30-40kg/ m3

Material: Polystyrene(PS)

Blowing agent: Freon(HFC,HCFC,CO2)

Standard configration

1 Mixing system

2 Feeding system

3 Primary extruder

4 Metering pump

5 Hydraulic screen changer

6 Secondary extruder

7 Slot die

8 Oil temperature controller

9 Board calibrator

10 First haul-off system

11 Take-off system

12 Cut-to-width system

13 Second haul-off system

14 Cut-to-length system

15 Electrical control equipment

* Margin recycle system (PTRECYCLERTM)

* Optional finishing machines

1 Embossing unit

2 Planer (Rough; Fine)

3 Groover (Straight; Dovetail)

4 Edge trimmer (SL; RC; TG)

5 Slice cutting machine

6 Aluminium foil composite machine

Features

.Sound technology! Reliable system!Main Products

XPS Production Line,XPS Extrusion line,XPS INSULATION LINE