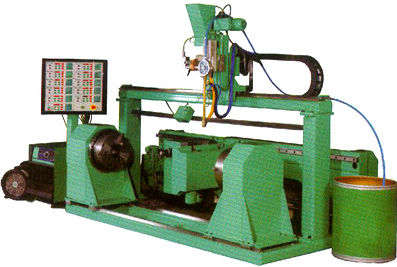

Automatic Hardfacing Machine

Automatic hardfacing machine of our advanced technology in extended wear life equipments, widely used in each kind of hot roller, beam steel roller, color metals roller, and grind coal roller, etc various works pieces to prepare to protect and repair the work; We can customize various different specifications according to customer’s need.

Main advantages:

1、 Realizing hardfacing process and heat preservation process synchronously, guaranteeing digital control between the surfacing layer temperatures in the process of hardfacing.

2、 Realizing welding of automatic recovery and avoiding the dust pollution, improving the working environment.

3、 Wire stability, wire torque in process of surfacing, which can realize high speed surfacing and swinging overlays, increased melting and depth of molten pool apply efficiency.

4、 Strengthen the arc of molten pool of electromagnetic and mechanical agitation role in the process of the swinging hardfacing, making the weld microstructure becomes more reasonable and uniform.

5、 It can achieve automation control for all the welding process parameters including the current, voltage, wire feeding speed, walk line speed, walk line distance, weld bead width, weld bead pendulum wide, welding time, etc.

Roll surfacing welding machine is a special kind of welding equipment; it is combined by head and tail welding positioner, submerged arc welding power, wheel frame etc. Welding machines’ basic classifications are according to the size of the loading, also with reference to length of the workpiece, and the workpiece parameters.

Main advantages:

1、 Realizing hardfacing process and heat preservation process synchronously, guaranteeing digital control between the surfacing layer temperatures in the process of hardfacing.

2、 Realizing welding of automatic recovery and avoiding the dust pollution, improving the working environment.

3、 Wire stability, wire torque in process of surfacing, which can realize high speed surfacing and swinging overlays, increased melting and depth of molten pool apply efficiency.

4、 Strengthen the arc of molten pool of electromagnetic and mechanical agitation role in the process of the swinging hardfacing, making the weld microstructure becomes more reasonable and uniform.

5、 It can achieve automation control for all the welding process parameters including the current, voltage, wire feeding speed, walk line speed, walk line distance, weld bead width, weld bead pendulum wide, welding time, etc.

Roll surfacing welding machine is a special kind of welding equipment; it is combined by head and tail welding positioner, submerged arc welding power, wheel frame etc. Welding machines’ basic classifications are according to the size of the loading, also with reference to length of the workpiece, and the workpiece parameters.

Main Products

welding equipment,cutting machine,beveling machine,milling machine