The substance of electromagnetic stirring (EMS) is to strengthen liquid steel motion by means of electromagnetic force induced in liquid core of strand. In the concrete, alternated magnet field excited by the stirrer penetrates into the liquid steel of strand and generates electromagnetic force under the interaction of induced current and local magnet field. The electromagnetic force is the volume force acted on the liquid steel volume, which can push liquid steel in motion so as to reach the aim of improving slab quality.

2. A large amount of practice shows that suitable electromagnetic stirring used in continuous casting can effectively improve the inner structure, raise surface quality, lighten central segregation and loosening, eliminate central contraction cavity and crack, and greatly increase equax crystal rate. Moreover, it can widen process condition of continuous casting and raise casting speed.

3. According to the installation positions, the electromagnetic stirrers are devided to Mold electromagnetic stirring(E-EMS); Strand electromagnetic stirring(SEMS); Final electromagnetic stirring(FEMS).

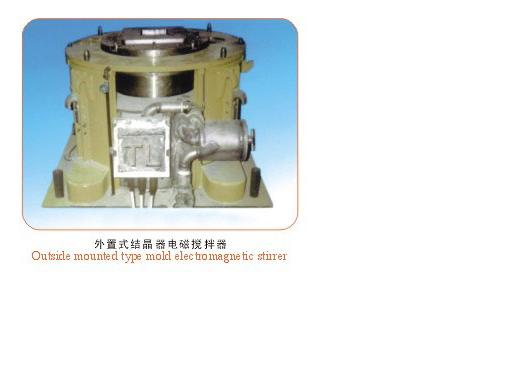

4. Mold electromagnetic stirring (M-EMS): stirrer is mounted outside of mold copper tube. All billet caster use rotary magnet field stirrer for M-EMS without any exception. Double-side traveling wave magnet field stirrers are used as M-EMS for slab casting. No matter the billet or slab casting, low frequency power excitations are adopted for M-EMS.

2. A large amount of practice shows that suitable electromagnetic stirring used in continuous casting can effectively improve the inner structure, raise surface quality, lighten central segregation and loosening, eliminate central contraction cavity and crack, and greatly increase equax crystal rate. Moreover, it can widen process condition of continuous casting and raise casting speed.

3. According to the installation positions, the electromagnetic stirrers are devided to Mold electromagnetic stirring(E-EMS); Strand electromagnetic stirring(SEMS); Final electromagnetic stirring(FEMS).

4. Mold electromagnetic stirring (M-EMS): stirrer is mounted outside of mold copper tube. All billet caster use rotary magnet field stirrer for M-EMS without any exception. Double-side traveling wave magnet field stirrers are used as M-EMS for slab casting. No matter the billet or slab casting, low frequency power excitations are adopted for M-EMS.

Main Products

lifting magnet