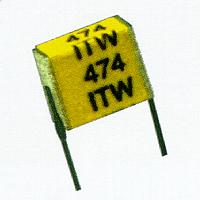

More than 10 years ago ITW Paktron developed the highly advanced Interleaf Technology method of manufacturing. Our plan was to produce a better film capacitor and position ourselves to meet the capacitor design needs well into the 21st century. One result of this technology is the self-encased, multi-layer-polymer Angstor(copyright) Capacitor Series. The Angstor offers efficient sizing(capacitance vs. Volume), high dv/dt (exceeding 100V/Musec for a .1MuF), no DC working voltage derating to 125 Celsius, and the highest quality construction. The self-sealed construction of the RA can withstand severe environments without the addition of costly encasements. The Angstor is an extremely rugged device able to survive severe temperatures and handling. It is an excellent filter or noise suppression device as its construction is essentially a monolithic block with virtually no air.

Specifications

- Efficient size.

- Rugged construction.

- Does not fail short-Self healing.

- Low ESR/ESL.

- No dissimilar metals to chemically degrade or attract moisture.

- High dv/dt.

- Wave solderable.

- Operating temperature range: -55 to +125 Celsius.

- Electrical

- Tolerance: Available in +/-5%, 10%, 20%.

- Dissipation factor: =1000Megohms x MuF. Need not exceed 1,000 Megohms. Test voltage @ one minute: 1)Rated voltage: 100VDC; 2)Test voltage: 10VDC/100VDC.

- Dielectric strength: 1.6 x WVDC, 2 Sec. 1.3 x WVDC,2 Sec.

- Self inductance: 2 to 6nh.

- Max. pulse rise rate: dv/dt: .1MuF, 100V/Mu Sec.

- Temperature range: -555 to 125 Celsius @ rated DC voltage; -55 to 85 Celsius for bold parts. For use at 125 Celsius derate voltage by 50%.

- Environmental:

- DC life: 1,000 hours, 85 Celsius, 1.25WVDC, Delta C/C < 5%. DF=10^3 Mohms x MuF.

- Moisture: EIARS-377, P 3.12, 72 hrs., Delta C/C < 7%. DF is=10^3 Mohms after 4 hrs. air dry.

- Long term stability: After 2 years storage, std. environment Delta C/C

Features

- EMI/RFI suppression:

- Applications for EMI/RFI suppression on a variety of motors or field effect devices to protect electronic engine computers and the ever increasing variety of automotive electronics. Noise and/or transients are generated from motors in wipers, window lifts are generated from motors in wipers, window lifts, cooling fans, blower fans, ABS and suspension controls/pumps, and seat controls. Metallized film capacitors should be chosen because they are inherently reliable and will fail open rather than fail short in the event of a catastrophic failure. The actual failure mechanism is a gradual loss in capacitance over a very long time, eventually going to an open state. The Angstor will handle the combinations of temperature shocks, voltage and current spikes, vibration. And be equal to, or exceed, the electrical performance of other dielectric.

- Pulse applications:

- In smaller gasoline engines and gas ignitors, a film capacitor is used as a high energy storage and discharge device for spark ignition. Small engines are used in chain saws, lawn mowers, snowblowers, string trimmers, stand-by generators and a variety of other consumer and commercial products. The Angstor's superior dv/dt is required in this classic pulse application. The plasma-welded leads provide a radial pull strength exceeding 15 1bs. The use of no dissimilar metals enhances the pulse handing characteristics of the Angstor.

- High frequency power applications:

- As the modern power supply broke the 200KHz switching frequency barrier, the ripple voltage filtering techniques changed drastically. LC(inductor/capacitor) filters must now be very small and efficient components. The choice of capacitors is shifting from electrolytic to electrostatic types. Because of the extremely low equivalent series resistance(ESR) and equivalent series inductance (ESL) OF THE Angstor, it is an excellent choice for this application. Larger and denser capacitors based upon Interleaf Technology manufacturing methods are now being designed for switching frequencies to 10 MHz.

- High temperatures:

- Applications include capacitors in the ballast starter, power factor correction in electronic ballast, and as filters in lighting dimmer/electronic controls. Two paktron advantages shine in these applications: the first, our construction makes the parts exhibit virtually no noise in frequency sensitive applications(50KHz+ in electronic ballast, or 60 cycle "hum" in dimmer controls). The second very important 125 Celsius with no voltage derating. Normal ballast temperature requirements are 105 Celsius and most competitors must derate working voltage above 85 Celsius using polyester film capacitors.

- Efficient size:

- Manufacturers of consumer products, motor speed controls, ground-fault circuit interruption(GFCI), telecommunications and many other electronic systems select the Angstor for its size. Compared to typical wound capacitors the Angstor is 30% smaller.

Main Products

switches, NLX motherboard, rail system, electronic plastic pants, urethane bumper foot, insulation - formex, lightning protector eon telecommunication