For some applications it may be necessary to improve the properties of PTFE. Resistance to wear, deformation under load, creep, thermal conductability, and co-efficient of expansion, can be improved by adding suitable fillers. The fillers normally used are minerals such as Glass Fiber, Carbon, Graphite, Metallic Powders (Bronze, Stainless Steel etc.) Ceramic, Sulfide and Metallic Oxide, the filling element is used at a percentage of between 10 to 35% of the volume. Filling elements improve the wear properties of PTFE from 10 to 500 times, the creep and compression resistance from 1.5 to 2, decrease the expansion co-efficient and increase thermal conductivity 2 to 3 time. Chemical resistance depends on the filler and only PTFE filled with Glass Fiber or Carbon (Graphite) have good chemical resistance.

Main Products

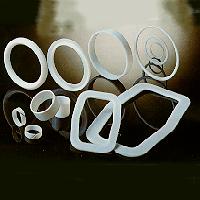

Teflon, ball, casting products