An injection molded wax pattern is used for each part produced and is then encased in multiple layers of ceramic material.

The wax pattern is then removed from the ceramic shell mold.

The mold is fired in an oven and then molten metal is poured into the cavities left by the evacuated wax pattern.

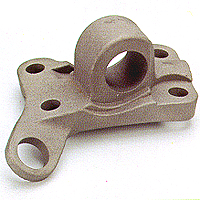

Upon cooling, the resulting precision castings are cleaned and subjected to further processing such as heat treatment.

At this point, many parts are in their final form and are ready for use.

The wax pattern is then removed from the ceramic shell mold.

The mold is fired in an oven and then molten metal is poured into the cavities left by the evacuated wax pattern.

Upon cooling, the resulting precision castings are cleaned and subjected to further processing such as heat treatment.

At this point, many parts are in their final form and are ready for use.

Main Products

investment, injection, mold, wax, limit of tolerance table