Fiber Cement Board is produced by mixing fine natural fibers, portland cement, and mineralizing agents. The mixed material is laid on carrier plates using a unique laying process. The carrier plates with the formed board mat are stacked and compressed using very high pressure to convert the formed mat into boards of required thickness. The stack is kept compressed until cement is hardened. The fresh boards are kept in the maturing store and passed through the conditioning chamber to bring them to equilibrium moisture content. The matured boards are trimmed to the finished size, thoroughly inspected for quality, and packed for dispatch.

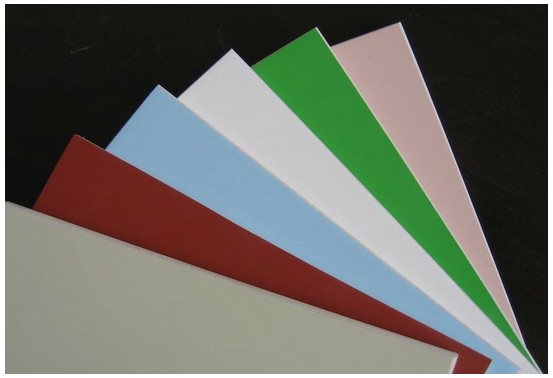

Fiber cement board is an environmentally-friendly and safe building product, so fiber cement board are widely applied for various interior and exterior applications where a smooth, flat surface is required for finishing off, cladding, siding, partitioning, and edging various projects.

Fiber cement board is an environmentally-friendly and safe building product, so fiber cement board are widely applied for various interior and exterior applications where a smooth, flat surface is required for finishing off, cladding, siding, partitioning, and edging various projects.

Certificate

- ISO9001

Main Products

roofing tile,wall cladding,fiber cement board,roof sheet