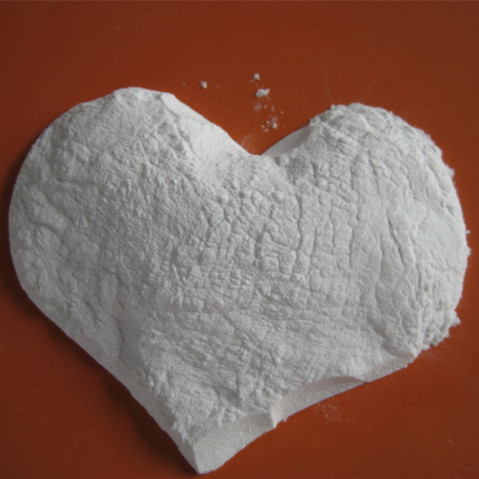

polishing materail

White aluminum oxide is an extremely sharp, long-lasting blasting abrasive that can be recycled many times after the initial media blasting. It is the most widely used abrasive in blast finishing and surface preparation because of its cost, longevity and hardness. Harder than other commonly used blasting materials, white aluminum oxide grains penetrate and cut even the hardest metals and sintered carbide.

Model: WA JIS#2500

Chemical compositions Physical properties

Items Value of specification (%) Items Property

Al2O3 99.2min Color White

SiO2 0.14max Bulk density 1.75-1.95g/cm3

Na2O 0.30max Real density 3.90g/cm3 min

Fe2O3 0.06max hardness 9

D50 5.5±0.5 Usage Polishing

Model: WA JIS#2500

Chemical compositions Physical properties

Items Value of specification (%) Items Property

Al2O3 99.2min Color White

SiO2 0.14max Bulk density 1.75-1.95g/cm3

Na2O 0.30max Real density 3.90g/cm3 min

Fe2O3 0.06max hardness 9

D50 5.5±0.5 Usage Polishing

Main Products

white /brown fused alumina/ green/black silicon carbide