Introduction

Sonic logging pipes are Push-Fit Solution dedicated for sonic test applications. They are specially designed to be encased in foundations such as bored piles, diaphragm walls and barrettes to allow for future testing of the concrete integrity by ultrasonic waves. The concept is to form a bell mouth by enlarging the end of the tube to allow a CONCRETE PROOF JOINT.

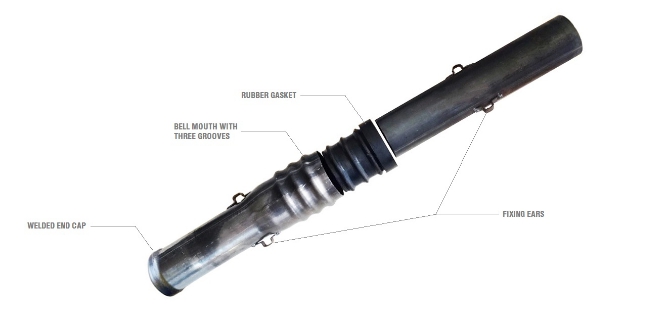

Bell Mouth:

Joint Rubber Gasket

Efficient concrete proof coupling.

Fixing Ears:

Stable and reliable connection to the rebar cage

Accessories:

Welded End Cap

Reinforced with welded end cap, it prevents entry of foreign material in the end tube.

Optional Crimping Tool

Easy, Quick & Safe, it ensures the tubes stay well connected.

Usage:

Petroleum, power, gas, chemical and medical equipment, construction, bridge, power engineering

Push Fit sonic pipes type 1& type

2 Specification:

OD (mm) Wall Thickness (mm) L (m)

46 1.0, 1.2, 1.5 5.8

50 1.0, 1.2, 1.5 5.8

54 1.0, 1.2, 1.5 5.8

57 1.0,

Sonic logging pipes are Push-Fit Solution dedicated for sonic test applications. They are specially designed to be encased in foundations such as bored piles, diaphragm walls and barrettes to allow for future testing of the concrete integrity by ultrasonic waves. The concept is to form a bell mouth by enlarging the end of the tube to allow a CONCRETE PROOF JOINT.

Bell Mouth:

Joint Rubber Gasket

Efficient concrete proof coupling.

Fixing Ears:

Stable and reliable connection to the rebar cage

Accessories:

Welded End Cap

Reinforced with welded end cap, it prevents entry of foreign material in the end tube.

Optional Crimping Tool

Easy, Quick & Safe, it ensures the tubes stay well connected.

Usage:

Petroleum, power, gas, chemical and medical equipment, construction, bridge, power engineering

Push Fit sonic pipes type 1& type

2 Specification:

OD (mm) Wall Thickness (mm) L (m)

46 1.0, 1.2, 1.5 5.8

50 1.0, 1.2, 1.5 5.8

54 1.0, 1.2, 1.5 5.8

57 1.0,

Main Products

REBAR COUPLERS, CORRUGATED STEEL PIPES, UPSET FORGING MACHINE