Ferrosilicon is an indispensable deoxidizer in the steel industry. Ferrosilicon is used for precipitation deoxidation and diffused deoxidation in steelmaking. Ferrosilicon is also used as an alloying agent in steelmaking. Add a certain amount of silicon into the steel can significantly improve the strength of steel, hardness and elasticity. Enhance the magnetic permeability of the steel, and reduce the hyteresis loss of the transformer steel.

Generally the steel contain 0.15%~0.35% silicon. The structural steel contains 0.40%~1.75% silicon. The tool steel contains 0.30%~1.80% silicon. The spring steel contain 0.40~2.80% silicon. The stainless acid resistant steel contains 3.40%~4.00% silicon. The heat-resistant steel contain 1.00%~3.00% silicon. The silicon steel contains 2%~3% silicon or more.

High silicon ferrosilicon or silicon alloy is used as the reducing agent of the production of low-carbon ferroalloy industry. Add ferrosilicon into cast iron can be as incubater of ductile iro

Generally the steel contain 0.15%~0.35% silicon. The structural steel contains 0.40%~1.75% silicon. The tool steel contains 0.30%~1.80% silicon. The spring steel contain 0.40~2.80% silicon. The stainless acid resistant steel contains 3.40%~4.00% silicon. The heat-resistant steel contain 1.00%~3.00% silicon. The silicon steel contains 2%~3% silicon or more.

High silicon ferrosilicon or silicon alloy is used as the reducing agent of the production of low-carbon ferroalloy industry. Add ferrosilicon into cast iron can be as incubater of ductile iro

Certificate

- ISO9000:2008

Main Products

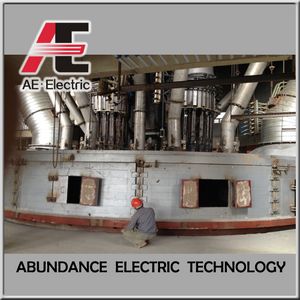

electric arc furnace, ladle refining furnace, submerged arc furnace