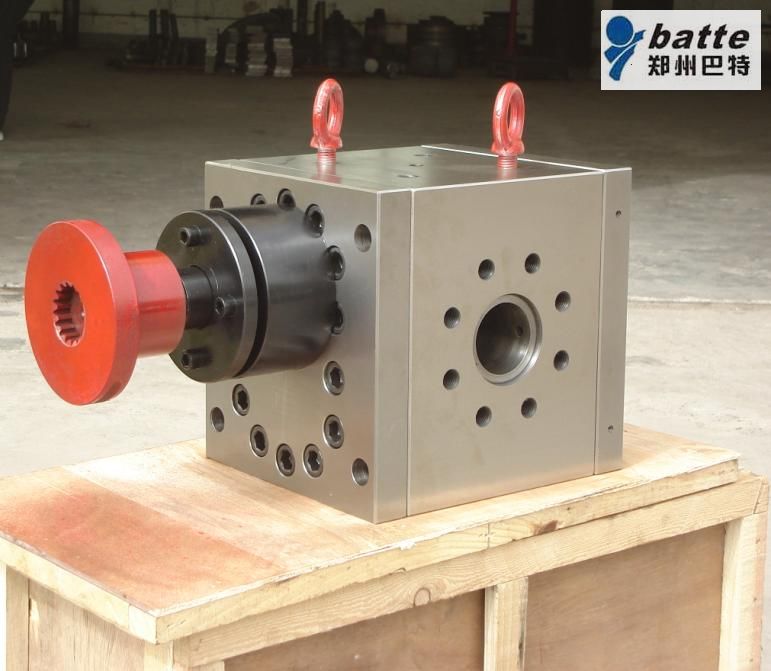

Technical data:

1.Rotate speed: ≤60rpm(Adjustable)

2.Temperature: 400℃ (max.)

3.Max.Outlet pressure: 350Bar

4.Max.Differential pressure: 275Bar

5.Heating method: Stainless Steel Cartridge Heater

6.Fastening parts: 12.9 high-strength screws

7.Voltage: 380V(Others are optional)

8.Frequency: 50Hz(Others are optional)

There are some advantages of gear pumps:

1. Elimination of output variations and pressure pulsations, thus improve the product quality

2. Optimization of the dimensional accuracy as well as of surface and optical quality with the production of films, sheets and profiles

3. Improvement of the product quality with regard to homogeneity and pellet size in the compounding

4. Saving of raw material, reduction of rejects

5. Increase of output

6. Decrease of energy consumption of the complex line

7. Conserving use of the extruder by means of process-technical shifting the task of building up pressure to the gear pump

1.Rotate speed: ≤60rpm(Adjustable)

2.Temperature: 400℃ (max.)

3.Max.Outlet pressure: 350Bar

4.Max.Differential pressure: 275Bar

5.Heating method: Stainless Steel Cartridge Heater

6.Fastening parts: 12.9 high-strength screws

7.Voltage: 380V(Others are optional)

8.Frequency: 50Hz(Others are optional)

There are some advantages of gear pumps:

1. Elimination of output variations and pressure pulsations, thus improve the product quality

2. Optimization of the dimensional accuracy as well as of surface and optical quality with the production of films, sheets and profiles

3. Improvement of the product quality with regard to homogeneity and pellet size in the compounding

4. Saving of raw material, reduction of rejects

5. Increase of output

6. Decrease of energy consumption of the complex line

7. Conserving use of the extruder by means of process-technical shifting the task of building up pressure to the gear pump

Main Products

gear pumps for extruders /melt pumps /srew loss-in-weight feeder