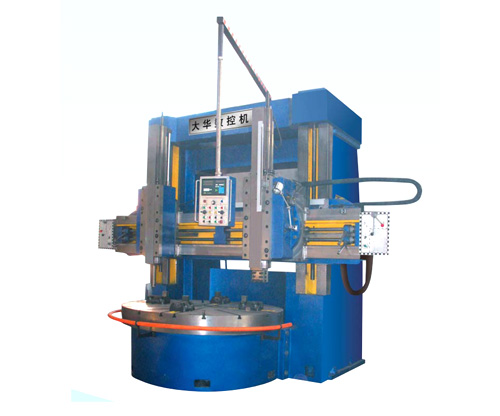

C5240 Double-column Vertical Lathe(www.cnlathes.com)

1. Modularization design and the general products are mature, stable and reliable.

2. Excellent casting (HT300) is treated by heat ageing.

3. The beam guide is handled by supersonic frequency induction hardening and it adopts rolling-sliding compound type. The vertical tool holder utilizes ductile iron materials while the sliding surface uses sticking plastic treatment with a durable performance.

4. Manual lubrication pump realizes oiling lubrication of different lubricating parts.

5. High-quality famous and exceptional electric components and Japan Omron PLC control guarantee high reliability.

6. The guide can be divided into such two types as static pressure and purely static pressure. The bearing of dynamic and static pressure is 10 ton; the purely static pressure adopts constant current for oil supply with 16-20 tons of bearing.

7. Independent hydraulic station facilitates adjustment, repair and maintenance.

8. Grating digital display device is equipped.

9. JB/T4116-96 precision test standard of vertical lathe is performed.

JB/3665-96 technical condition of vertical lathe is performed.

10. Complete processing and assembly process and strict quality control flow ensure the products reach perfect and first0class perfect quality.

11. High-precision speed-changing gear (Grade 6 precision) and high-precision gear grinding spiral bevel gear (Grade 6 precision) are featured with of low noise and stable operation.

12. One-year quality assurance service is granted (installation, debugging and after-sales service).

1. Modularization design and the general products are mature, stable and reliable.

2. Excellent casting (HT300) is treated by heat ageing.

3. The beam guide is handled by supersonic frequency induction hardening and it adopts rolling-sliding compound type. The vertical tool holder utilizes ductile iron materials while the sliding surface uses sticking plastic treatment with a durable performance.

4. Manual lubrication pump realizes oiling lubrication of different lubricating parts.

5. High-quality famous and exceptional electric components and Japan Omron PLC control guarantee high reliability.

6. The guide can be divided into such two types as static pressure and purely static pressure. The bearing of dynamic and static pressure is 10 ton; the purely static pressure adopts constant current for oil supply with 16-20 tons of bearing.

7. Independent hydraulic station facilitates adjustment, repair and maintenance.

8. Grating digital display device is equipped.

9. JB/T4116-96 precision test standard of vertical lathe is performed.

JB/3665-96 technical condition of vertical lathe is performed.

10. Complete processing and assembly process and strict quality control flow ensure the products reach perfect and first0class perfect quality.

11. High-precision speed-changing gear (Grade 6 precision) and high-precision gear grinding spiral bevel gear (Grade 6 precision) are featured with of low noise and stable operation.

12. One-year quality assurance service is granted (installation, debugging and after-sales service).

Main Products

Vertical lathe CNC vertical lathe