Application Scope:

Cylinder Oil-Cylinder Pneumohydraulic Cylinder Pneumatic Presser

Hydraulic Presser Pneumohydraulic Drives Machine

Product Characteristics:

Visual, digital, integrated, efficient and economic, reducing users’ cost and development leadtime, improving competitiveness.

Function Description:

1. Greatly improve the visualization and digitization by adopting SCM control and LCD screen , integrate relays inside the machine , connect a solenoid valve and begin to work , reduce the periphery circuits cost of the ordinary relays’ controller.

2. Each controller is able to output three 24V DC signals, control at most three solenoid valves, three cylinders or three Oil- cylinders, run independently or dependently. Or controlling a two five-way solenoid valve or a three five-way solenoid valve.

3. Control three motors, or alternatively use the motor, cylinder and Oil- Cylinder to form a automatic equipment.

4. Driving many cylinders or Oil-Cylinders to realize a state of multi-stations, produce multi-stations pneumatic press .

5. Realize the function of the tip operation on the cylinder or the Oil-Cylinder.

6. Control the pneumohydraulic cylinder with the tip operation.

7. Independently set the time of those three output ways with a precision of 0.1s.

8. Set the times of work automatically, stop working when the times is enough; set the time of work and the pace of work automatically.

9. Equip a control interface for temperature or pressure. Connect a sensor to control the temperature or pressure.

10. Running modes: automatic operation, manual operation, forward tip made, reverse tip mode.

11. Set the latency of fast forward and the record (the standby time and dwell time) with a precision of 0.1s.

Cylinder Oil-Cylinder Pneumohydraulic Cylinder Pneumatic Presser

Hydraulic Presser Pneumohydraulic Drives Machine

Product Characteristics:

Visual, digital, integrated, efficient and economic, reducing users’ cost and development leadtime, improving competitiveness.

Function Description:

1. Greatly improve the visualization and digitization by adopting SCM control and LCD screen , integrate relays inside the machine , connect a solenoid valve and begin to work , reduce the periphery circuits cost of the ordinary relays’ controller.

2. Each controller is able to output three 24V DC signals, control at most three solenoid valves, three cylinders or three Oil- cylinders, run independently or dependently. Or controlling a two five-way solenoid valve or a three five-way solenoid valve.

3. Control three motors, or alternatively use the motor, cylinder and Oil- Cylinder to form a automatic equipment.

4. Driving many cylinders or Oil-Cylinders to realize a state of multi-stations, produce multi-stations pneumatic press .

5. Realize the function of the tip operation on the cylinder or the Oil-Cylinder.

6. Control the pneumohydraulic cylinder with the tip operation.

7. Independently set the time of those three output ways with a precision of 0.1s.

8. Set the times of work automatically, stop working when the times is enough; set the time of work and the pace of work automatically.

9. Equip a control interface for temperature or pressure. Connect a sensor to control the temperature or pressure.

10. Running modes: automatic operation, manual operation, forward tip made, reverse tip mode.

11. Set the latency of fast forward and the record (the standby time and dwell time) with a precision of 0.1s.

Main Products

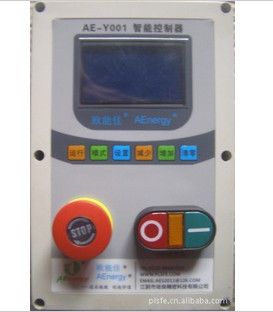

intelligent controller