Performance Characteristics:

Widely used cold work mould steel, with good quench-hardening ability, good wear resistance ,as well hot workability.

Applications:

Making efficient blanking mould, stamping mould, all kinds of scissors ,cold shearing ,drilling bushing ,gauge, wortle, coining die, thread rolling die, screw thread rolling die,cold extrusion dies .

Chemical Composition (%):

C :2.00~2.30 Si:≤0.40 Mn:≤0.40 S :≤0.030 P :≤0.030 Cr:11.50~13.00 Ni:≤0.25 Cu:≤0.30 Co:≤1.00

Heat treatment standard:

(1) Quenching, 950 ~ 1000 centigrade cold oil;

(2) Quenching 980 centigrade, cold oil, 180 centigrade tempering 2 hours

Annealing temperature: 800-850 Centigrade

Annealing hardness: 248 HB Max.

Destressing temperature: 650 Centigrade Approx.

Hot forming temperature: 1050-850 Centigrade

Quenching temperature: 940-970 Centigrade

Hardening media: oil quenching, salt bath 220-250 Centigrade or 500-550 Centigrade, air or compressed air.

Quenching hardness: 63-65 HRC

Delivery condition :

Annealed

Widely used cold work mould steel, with good quench-hardening ability, good wear resistance ,as well hot workability.

Applications:

Making efficient blanking mould, stamping mould, all kinds of scissors ,cold shearing ,drilling bushing ,gauge, wortle, coining die, thread rolling die, screw thread rolling die,cold extrusion dies .

Chemical Composition (%):

C :2.00~2.30 Si:≤0.40 Mn:≤0.40 S :≤0.030 P :≤0.030 Cr:11.50~13.00 Ni:≤0.25 Cu:≤0.30 Co:≤1.00

Heat treatment standard:

(1) Quenching, 950 ~ 1000 centigrade cold oil;

(2) Quenching 980 centigrade, cold oil, 180 centigrade tempering 2 hours

Annealing temperature: 800-850 Centigrade

Annealing hardness: 248 HB Max.

Destressing temperature: 650 Centigrade Approx.

Hot forming temperature: 1050-850 Centigrade

Quenching temperature: 940-970 Centigrade

Hardening media: oil quenching, salt bath 220-250 Centigrade or 500-550 Centigrade, air or compressed air.

Quenching hardness: 63-65 HRC

Delivery condition :

Annealed

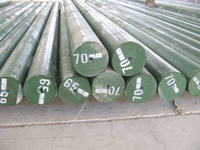

Main Products

mould steel