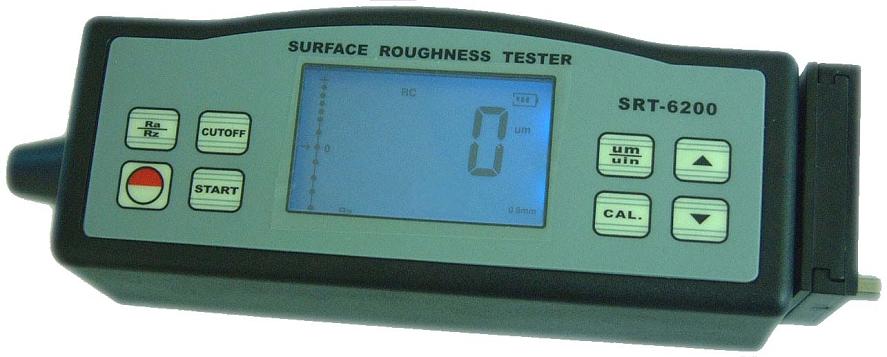

his instrument is compatible with four standards of

ISO, DIN, ANSI and JIS and is widely used in production

site to measure surface roughness of various

machinery-processed parts, calculate corresponding

parameters according to selected measuring conditions

and clearly display all measurement parameters.

When measuring the roughness of a surface, the

sensor is placed on the surface and then uniformly

slides along the surface by driving the mechanism

inside the tester. The sensor gets the surface roughness

by the sharp built-in probe. This roughness causes

displacement of the probe which results in change of

inductive amount of induction coils so as to generate

analogue signal, which is in proportion to the surface

roughness at output end of phase-sensitive rectifier.

The exclusive DSP processes and calculates and then

outputs the measurement results on LCD.

ISO, DIN, ANSI and JIS and is widely used in production

site to measure surface roughness of various

machinery-processed parts, calculate corresponding

parameters according to selected measuring conditions

and clearly display all measurement parameters.

When measuring the roughness of a surface, the

sensor is placed on the surface and then uniformly

slides along the surface by driving the mechanism

inside the tester. The sensor gets the surface roughness

by the sharp built-in probe. This roughness causes

displacement of the probe which results in change of

inductive amount of induction coils so as to generate

analogue signal, which is in proportion to the surface

roughness at output end of phase-sensitive rectifier.

The exclusive DSP processes and calculates and then

outputs the measurement results on LCD.

Certificate

- CE

- ROHS

Main Products

instrument and meter