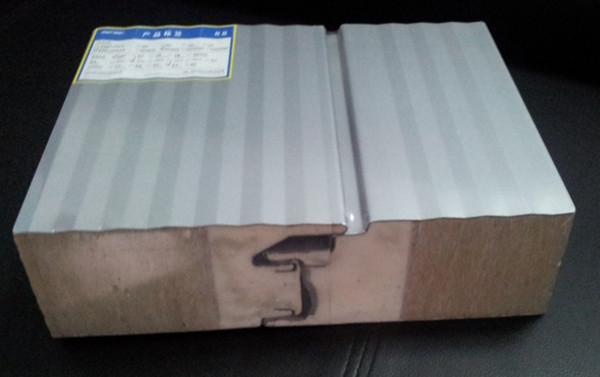

Rock wool sandwich panels are made by color filament fibers of rock wool in the core. They are profiled by automated continuous forming machine and adhesive bonded later.

It has the characteristics sound insulation and fire-proof, fast installation speed, durability, and beautiful appearance, etc. so it is widly used as roofing material for steel structure plant, gym, Supermatet ,commercial and civilian facilities.

Material:

1.The thickness of up/ lower steel panel:0.2mm-0.8mm color-coated panel/zinc plate,hot galvanized plate/stainless steel panel

2.Core material-The density of this rockwool is 120kg/m3

3.Side steel stripe or not:0.2mm-0.8mm galvanized plate

Conformation:

It uses flame retardant rock wool as core material,and zinc-plated&color-coated steel sheets as the upper and bottom sheets.The panels are formed by heating and pressing with high-intensity glue through high-speed continuous forming machines

It has the characteristics sound insulation and fire-proof, fast installation speed, durability, and beautiful appearance, etc. so it is widly used as roofing material for steel structure plant, gym, Supermatet ,commercial and civilian facilities.

Material:

1.The thickness of up/ lower steel panel:0.2mm-0.8mm color-coated panel/zinc plate,hot galvanized plate/stainless steel panel

2.Core material-The density of this rockwool is 120kg/m3

3.Side steel stripe or not:0.2mm-0.8mm galvanized plate

Conformation:

It uses flame retardant rock wool as core material,and zinc-plated&color-coated steel sheets as the upper and bottom sheets.The panels are formed by heating and pressing with high-intensity glue through high-speed continuous forming machines

Main Products

polyurethane, EPS, rockwool, glass wool and cleanroom sandwich panels)