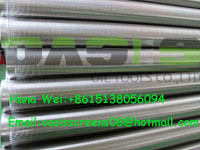

V-Wire water well screens are manufactured using our unique computerized machinery, developed in-house, and in which a continuous length of profile wire of a triangular section is fusion welded onto support rods.

This V shaped profile wire is wound around the support rods over the full length of the screen thus creating a continuous slot opening.

Metal Well Screens offer many advantages including:

A continuous slot opening which significantly increases the available open area, thus providing greater access to the water bearing zone (the aquifer)

A "V" shaped profile wire which avoids clogging and ensures an uninterrupted flow.

A uniform and efficient well development due to the continuous slot opening.

TECHNICAL DETAILS

Slot (mm)

Standards : 0,25 0,50 0,75 1,00 1,50 2,00 3,00.

Customized slots

Materials of Construction:

AISI 304 & 316 grade Stainless Steel, Low Carbon Steel, Galvanized Steel.

Screen lengths (meters)

Standard lengths : 2,90 m & 3 m or 5,80 m

This V shaped profile wire is wound around the support rods over the full length of the screen thus creating a continuous slot opening.

Metal Well Screens offer many advantages including:

A continuous slot opening which significantly increases the available open area, thus providing greater access to the water bearing zone (the aquifer)

A "V" shaped profile wire which avoids clogging and ensures an uninterrupted flow.

A uniform and efficient well development due to the continuous slot opening.

TECHNICAL DETAILS

Slot (mm)

Standards : 0,25 0,50 0,75 1,00 1,50 2,00 3,00.

Customized slots

Materials of Construction:

AISI 304 & 316 grade Stainless Steel, Low Carbon Steel, Galvanized Steel.

Screen lengths (meters)

Standard lengths : 2,90 m & 3 m or 5,80 m

Certificate

- ISO9001:2008

Main Products

water well screens/Johnson screens, oil well screens and sand control