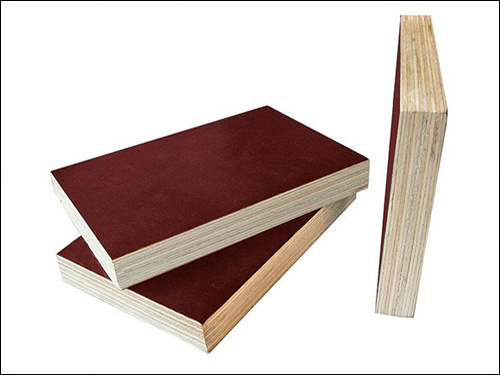

high quality two times hot press plywood, poplar core, and the melamine is made by ourself, light weiht, and smooth surface

Construction plywood produced by GIGA use high-quality poplar as main material, and use phenol aldehyde resin which has good bonding strength and water resistance. Through the advanced. through the advanced and strict technology,the phenol water template has many good features including smooth surface, high strength,light weight, good water resistance and it can be used for many times.it is suitable for concrete pouring of all kinds of construction projects.

and welcome to visit our website www.plywood-giga.com

It’s advantageous to winter construction for the excellent heat preservation performance

we have thickness 12mm,13mm,14mm,15mm,16mm,17mm,18mm

size: 1220*2440 915*1830 mm

core: poplar

glue: WBP and Melamine

How to cut best

Always clean and repair the formwork panels before storage. The formwork should then be stacked off the ground on level supports and under cover. Framed formwork panels should be stacked alternately face and back to back to avoid face damages by bolts etc. If panels are wet, do not allow them to dry too rapidly.

Sealing of edges

Phenolic fabric film faced plywood edges are fully sealed at the factory and it is the most important that all edges remain sealed. To obtain full value from a phenolic fabric film faced sheet any recut edges should sealed as soon as possible with water proof paint.

Cleaning and repair

To obtain full life, cleaning should be carried out immediately after each use. Phenolic fabric film faced plywood may be wiped with release agent or cleaned with water and stiffbrush .

and welcome to visit our website www.plywood-giga.com

It’s advantageous to winter construction for the excellent heat preservation performance

we have thickness 12mm,13mm,14mm,15mm,16mm,17mm,18mm

size: 1220*2440 915*1830 mm

core: poplar

glue: WBP and Melamine

How to cut best

Always clean and repair the formwork panels before storage. The formwork should then be stacked off the ground on level supports and under cover. Framed formwork panels should be stacked alternately face and back to back to avoid face damages by bolts etc. If panels are wet, do not allow them to dry too rapidly.

Sealing of edges

Phenolic fabric film faced plywood edges are fully sealed at the factory and it is the most important that all edges remain sealed. To obtain full value from a phenolic fabric film faced sheet any recut edges should sealed as soon as possible with water proof paint.

Cleaning and repair

To obtain full life, cleaning should be carried out immediately after each use. Phenolic fabric film faced plywood may be wiped with release agent or cleaned with water and stiffbrush .

Certificate

- CE ISO9001

Main Products

Filmfaced plywood

Contact Detail

-

Sales Contact18630920569