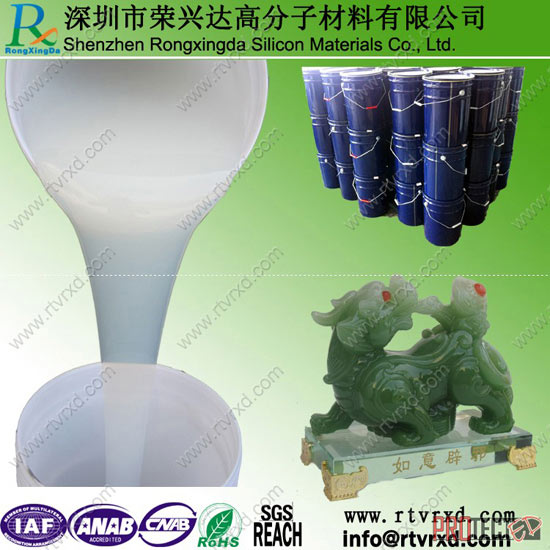

RTV-1300 ,LOW PRICE AND GOOD QUALITY

FEATURES

Good flowability and long working time

Medium hardness

High tear and tensile strength

Easy de-mould from complex replica parts

Acid and alkali-resistance

Low linear shrinkage

APPLICATIONS

RXD RTV-1300 is suited for reproduction of cement molding, concrete stones,

artificial stones, plaster molding, figures, art objects, decoration molding,

GRC products, gypsum products, resin products ,PU molds. etc..

DESCRIPATION

RXD RTV-1300 mold making silicone rubber is a two-component material silicone

rubber,consisting of Part A base silicone and Part B organic tin curing

agent,cures at room temperature by a condensation reaction.These materials

can be cast into the cured silicone

mold:plaster,polyurethane,PU,GRC,cement,resin,polyester,wax etc..

Standard Datasheet of Addition molding silicone rubber

Gel-type Components A B

Appearance (liquid) transparent

Mixing ratio 10 :1

Viscosity (Pa.s) 80000

Pot life(25C) (mins) 60

Curing time (mins) 24h

Hardness shore A 45

Tensile strength (Mpa) 6.7

Elongation at break (%) 350

Tear strength shore A 25

STORAGE

When stored at or below 30°C in the original unopened containers,SILASTIC

RTV-1300 Base and Curing agent have a usable life of 12 months.from the date

of production.After 12 months stock,pls use the Stir to mixing the Part A

silicone for some mins, then the silicone can be use again,no influence for

other performance.

Packing

1kg/drum,5kg/drum,20kg/drum,25kg/drum or 200kg/drum of Part A base silicone

rubber.

0.25kg/bottle,1kg/bottle and 10kg/bottle of Part B organic tin Curing Agent.

Good flowability and long working time

Medium hardness

High tear and tensile strength

Easy de-mould from complex replica parts

Acid and alkali-resistance

Low linear shrinkage

APPLICATIONS

RXD RTV-1300 is suited for reproduction of cement molding, concrete stones,

artificial stones, plaster molding, figures, art objects, decoration molding,

GRC products, gypsum products, resin products ,PU molds. etc..

DESCRIPATION

RXD RTV-1300 mold making silicone rubber is a two-component material silicone

rubber,consisting of Part A base silicone and Part B organic tin curing

agent,cures at room temperature by a condensation reaction.These materials

can be cast into the cured silicone

mold:plaster,polyurethane,PU,GRC,cement,resin,polyester,wax etc..

Standard Datasheet of Addition molding silicone rubber

Gel-type Components A B

Appearance (liquid) transparent

Mixing ratio 10 :1

Viscosity (Pa.s) 80000

Pot life(25C) (mins) 60

Curing time (mins) 24h

Hardness shore A 45

Tensile strength (Mpa) 6.7

Elongation at break (%) 350

Tear strength shore A 25

STORAGE

When stored at or below 30°C in the original unopened containers,SILASTIC

RTV-1300 Base and Curing agent have a usable life of 12 months.from the date

of production.After 12 months stock,pls use the Stir to mixing the Part A

silicone for some mins, then the silicone can be use again,no influence for

other performance.

Packing

1kg/drum,5kg/drum,20kg/drum,25kg/drum or 200kg/drum of Part A base silicone

rubber.

0.25kg/bottle,1kg/bottle and 10kg/bottle of Part B organic tin Curing Agent.

Certificate

- ISO SGS ROSH

Main Products

liquid silicone rubber