VCI Paper

VCI paper is made and refined from excellent antirust base paper and high efficient and compounded special VCI LIQUID with specific production technology. In the confined space with sealed packaging, VCI contained in the paper begins to sublimate and volatilize the antirust gas factors which diffuse and penetrate into the surfaces of the articles for antirust and adhere on them to form a compact protection film with the thickness of monomolecular, thus the corrosion is effectively prevented.

Features/Advantages:

1 The paper makes oil-free packaging available, and no coating, degreasing or cleaning procedure is required, which saves labor, time and cost.

2 VCI with high performance contained uniformly in the antirust paper will play a role of antirust soon after it is sealed in a package.

3 Even if the paper does not contact the metal directly, it can effectively perform the function of antirust, so it is especially applicable to metal products with complex appearance.

4 The paper has both functions of antirust and packaging.

5 The paper has the advantages of low cost and easy operation over vacuum package.

6 The paper is clean, harmless and non-toxic, so it is safe to environment. It passes SGS certification and meets RoHS directives.

Application Method:

1 The antirust paper shall contact the articles for antirust as closely as possible, without any barriers between them.

2 Before being packed, the surfaces of the articles for antirust shall remain clean and dry without impurities on them.

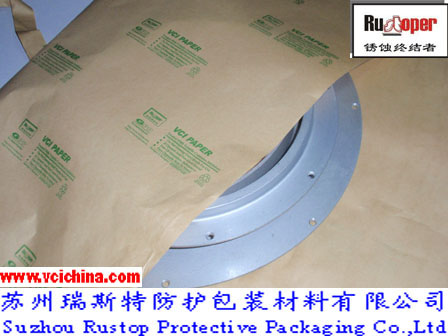

3 In case the surfaces of the articles for antirust are regular in their shape, the articles can be completely covered individually with the VCI paper (the utilization area of VCI paper shall be about the same as the surface area of the article) and then their joints shall be sealed. VCI paper can also be used as inner lining or interlayer packing paper in a sealed packaging unit (container, plastic bag, etc.).

4 Operate with clean gloves, and do not contact the articles for antirust with naked hands.

Features/Advantages:

1 The paper makes oil-free packaging available, and no coating, degreasing or cleaning procedure is required, which saves labor, time and cost.

2 VCI with high performance contained uniformly in the antirust paper will play a role of antirust soon after it is sealed in a package.

3 Even if the paper does not contact the metal directly, it can effectively perform the function of antirust, so it is especially applicable to metal products with complex appearance.

4 The paper has both functions of antirust and packaging.

5 The paper has the advantages of low cost and easy operation over vacuum package.

6 The paper is clean, harmless and non-toxic, so it is safe to environment. It passes SGS certification and meets RoHS directives.

Application Method:

1 The antirust paper shall contact the articles for antirust as closely as possible, without any barriers between them.

2 Before being packed, the surfaces of the articles for antirust shall remain clean and dry without impurities on them.

3 In case the surfaces of the articles for antirust are regular in their shape, the articles can be completely covered individually with the VCI paper (the utilization area of VCI paper shall be about the same as the surface area of the article) and then their joints shall be sealed. VCI paper can also be used as inner lining or interlayer packing paper in a sealed packaging unit (container, plastic bag, etc.).

4 Operate with clean gloves, and do not contact the articles for antirust with naked hands.

Certificate

- ISO9001:2008

Main Products

Rust preventive paper,plastic bag,packing film,VCI antirust agent