SF diamond Co.,Ltd provides both resin bond diamond grinding wheel and vitrified bond diamond grinding wheel.

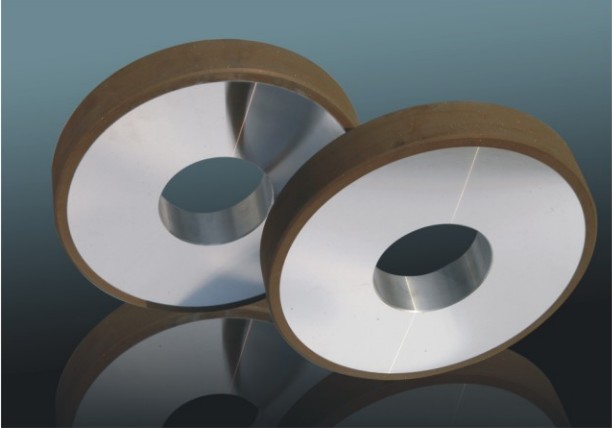

RESIN BOND DIAMOND WHEELS

Resin Bond Diamond Grinding Wheels have a special function of self-sharping, sharp-cutting, high-efficient grinding. It is not easy to destroy and heat the workpiece in grinding. After grinding, the workpieces surface is fine and smooth.

Resin Bond Diamond Wheel are mainly used in grinding carbide, vitrified, magnetic, silic, self-fluxing alloy material.

VITRIFIED BOND DIAMOND GRINDING WHEELS

The Vitrified Bond Diamond Grinding Wheels feature with high strength, high heat resistance, excellent cutting ability and high grinding efficiency, therefore, heating up or blacking is not easy to occur in the grinding process, and the low thermal dilation provide a high possibility of free control of process precision.

Vitrified Bond Diamond Grinding Wheels are applied in many hard and brittle material machining, such as wafer (semiconductor silicon

RESIN BOND DIAMOND WHEELS

Resin Bond Diamond Grinding Wheels have a special function of self-sharping, sharp-cutting, high-efficient grinding. It is not easy to destroy and heat the workpiece in grinding. After grinding, the workpieces surface is fine and smooth.

Resin Bond Diamond Wheel are mainly used in grinding carbide, vitrified, magnetic, silic, self-fluxing alloy material.

VITRIFIED BOND DIAMOND GRINDING WHEELS

The Vitrified Bond Diamond Grinding Wheels feature with high strength, high heat resistance, excellent cutting ability and high grinding efficiency, therefore, heating up or blacking is not easy to occur in the grinding process, and the low thermal dilation provide a high possibility of free control of process precision.

Vitrified Bond Diamond Grinding Wheels are applied in many hard and brittle material machining, such as wafer (semiconductor silicon

Certificate

- ISO9001:2008

Main Products

PCD