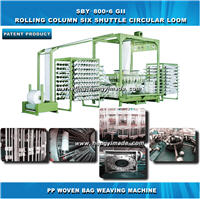

Rolling column six shuttles circular loom is our patent product, which have awarded the prizes of "high quality product", "new designed product", "new sciences techniques product" by "CPA" & "CPPA" of China.

Compare with other textile machinery in the present market of pp woven bag making machinery, our six shuttle circular loom has evident characters as follows:

1. High efficiency: There are six shuttles of the loom machine and the normal speed of main engine can be 150 r/min(tape width 2.5mm, normal running speed as the lowest parts consumption level), daily production capacity can more than 3, 000 meters.

2. Low noice: Adopt the hyperbola cam to drive the double guiding block, make the pale frame to go up and down, under the advaned and reasonable oil lubrication system, few spare parts wil spend on it after yearly running.

3. Automatic stop system and excellent fibers broken or finish detection device: For the warps we have equip warp broken detection system, when the warps broken or finished, the loom will stop immediately and show the area where the warp was finished or broken. For the weft, during the shuttle runing, the weft detection will send the signal continous, when the wefts finished or broken, the signal will stop, then the machine stop immediately, make sure you benefit to reduce the unqualified produced.

4. High flatness: Due to we follow the reasonable structure of rolling column, double guiding block, PP woven cloth produced by our circular loom have very high flatness, no fibers crowded.

5. Low quality requirement of flat fibers: Our circular loom can weave the flat fibers under 500~1800 denier (56~200 tex), this is the actual vaule data. Our circular loom can weave the bags which its square meters can be only 38 gram, no matter your fibers is produced by recycled material or virginal material, ccall be woven by our looms.

6. Low power consumption, our circular loom can weave 10, 000 meters PP woven tubal cloth only cost 200 kwh. As the energy price increased, no one doubt this type circular loom will be idea equipment for weaving PP woven bags.

Follow the market demand as the guider, we will work hard, to design and manufacture the best quality circular loom for you. Make the most profit for our customer is the target we always followed.

If you have any questions about our machines please feel free to contact with us.

Compare with other textile machinery in the present market of pp woven bag making machinery, our six shuttle circular loom has evident characters as follows:

1. High efficiency: There are six shuttles of the loom machine and the normal speed of main engine can be 150 r/min(tape width 2.5mm, normal running speed as the lowest parts consumption level), daily production capacity can more than 3, 000 meters.

2. Low noice: Adopt the hyperbola cam to drive the double guiding block, make the pale frame to go up and down, under the advaned and reasonable oil lubrication system, few spare parts wil spend on it after yearly running.

3. Automatic stop system and excellent fibers broken or finish detection device: For the warps we have equip warp broken detection system, when the warps broken or finished, the loom will stop immediately and show the area where the warp was finished or broken. For the weft, during the shuttle runing, the weft detection will send the signal continous, when the wefts finished or broken, the signal will stop, then the machine stop immediately, make sure you benefit to reduce the unqualified produced.

4. High flatness: Due to we follow the reasonable structure of rolling column, double guiding block, PP woven cloth produced by our circular loom have very high flatness, no fibers crowded.

5. Low quality requirement of flat fibers: Our circular loom can weave the flat fibers under 500~1800 denier (56~200 tex), this is the actual vaule data. Our circular loom can weave the bags which its square meters can be only 38 gram, no matter your fibers is produced by recycled material or virginal material, ccall be woven by our looms.

6. Low power consumption, our circular loom can weave 10, 000 meters PP woven tubal cloth only cost 200 kwh. As the energy price increased, no one doubt this type circular loom will be idea equipment for weaving PP woven bags.

Follow the market demand as the guider, we will work hard, to design and manufacture the best quality circular loom for you. Make the most profit for our customer is the target we always followed.

If you have any questions about our machines please feel free to contact with us.

Certificate

- 9001:2008

Main Products

pp woven bag making machines, extruder, circular loom, printing machin