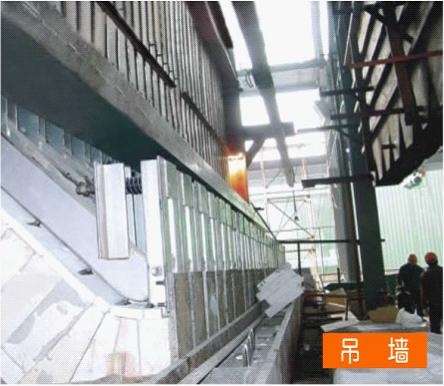

L suspended wall

The L-shaped wall is used at the front wall of the furnace.

The distance between the foot line of L-shaped wall and top surface of sidewall is short, which allows thinner batch feeding so that the batch can be melted more easily. It can also reduce fire and batch running at the charge end and hence energy can be saved and environment improved.With its high reliability and long service life span, the L-shaped suspended back wall serves as one of the essential measures for prolonging the whole furnace life.

Main Technical Index:

1. Modulus width of suspended wall: 300mm;

2. Width of brick structure: 380mm;

3. Length of nose zone (doghouse): 1700-2300mm;

4. Service life: more than 10 years.

The working atmosphere of the melting section and working section is effectively separated.

Main Technical Index:

1. Width of brick structure: 250mm

2. Service life: more than 15 years.

The distance between the foot line of L-shaped wall and top surface of sidewall is short, which allows thinner batch feeding so that the batch can be melted more easily. It can also reduce fire and batch running at the charge end and hence energy can be saved and environment improved.With its high reliability and long service life span, the L-shaped suspended back wall serves as one of the essential measures for prolonging the whole furnace life.

Main Technical Index:

1. Modulus width of suspended wall: 300mm;

2. Width of brick structure: 380mm;

3. Length of nose zone (doghouse): 1700-2300mm;

4. Service life: more than 10 years.

The working atmosphere of the melting section and working section is effectively separated.

Main Technical Index:

1. Width of brick structure: 250mm

2. Service life: more than 15 years.

Main Products

factory design for sheet/float/patterned glass, glass equipment,