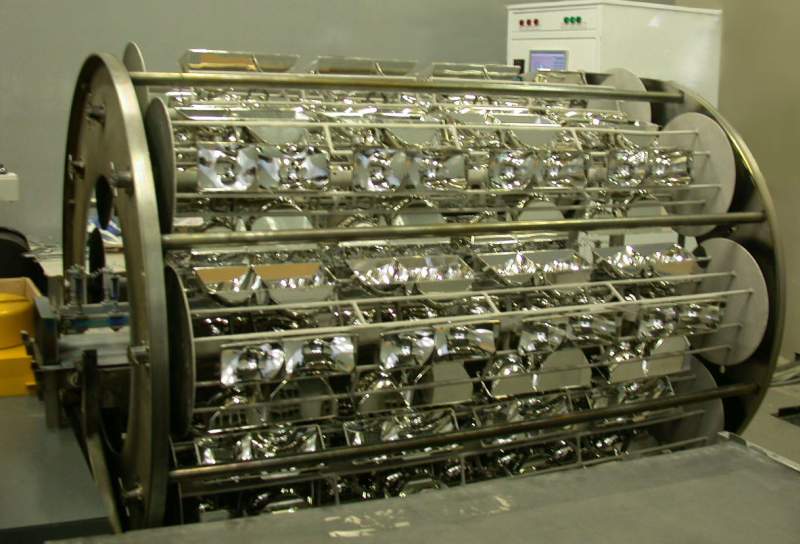

VATT-2000-ED vacuum coater

Is capable for applying various decorative and protective-decorative coatings on great variety of articles and may be used for modification of optical properties of 1600x2400 glass by means of titanium and titanium compounds deposition with arc cathode.

Arc sputtering method have been long used in vacuum equipment for application of thin films. High level of plasma ionization, high average ion energy and its controllability enables you to easily get metal oxide and metal nitride films as well as pure metal coats of required properties.

Technical features

* Production output. . . 7. 68 m2 / cycle;

* End vacuum. . 5*10-5 mm. Hg. Max;

* 1*10-4 mm Hg achievement time. . . 30 min max;

* Cooling water consumption. . . 1. 2 m3 / h at most;

* Average power consumption. . . 28 kW;

* Peak power consumption. . . 38 kW;

* Dimensions when the lid is open. . . 5500x3200x2800

Is capable for applying various decorative and protective-decorative coatings on great variety of articles and may be used for modification of optical properties of 1600x2400 glass by means of titanium and titanium compounds deposition with arc cathode.

Arc sputtering method have been long used in vacuum equipment for application of thin films. High level of plasma ionization, high average ion energy and its controllability enables you to easily get metal oxide and metal nitride films as well as pure metal coats of required properties.

Technical features

* Production output. . . 7. 68 m2 / cycle;

* End vacuum. . 5*10-5 mm. Hg. Max;

* 1*10-4 mm Hg achievement time. . . 30 min max;

* Cooling water consumption. . . 1. 2 m3 / h at most;

* Average power consumption. . . 28 kW;

* Peak power consumption. . . 38 kW;

* Dimensions when the lid is open. . . 5500x3200x2800

Main Products

vacuum coating equipment for glass, mirror production lines,