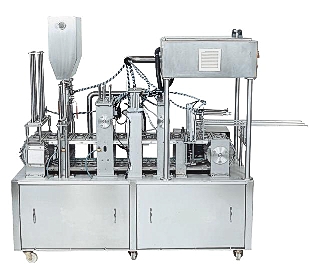

ASL-2 YOGURT AND MILK CUP FILLING MACHINE

Thanks to its photocell control. The machine is able to stop the filling operation if should any cup not be positioned correctly for filling. The machine accomplishes the process of filling and covering the cups very well that the machine operates without any product loss.

The completed bowls are lined by the conveyor on the arranging table the workers can pick them easily. This system is the most ideal one in terms of handling the product.

Operation System: It drops the plastic bowls automatically. The photocell controls the process of filling and covering the containers. The sealing process is accomplished with the use of heat. Packaging dates are applied in ink and the products are lined up on the table for easy handling.

Capacity 2800 cups / per hour

Voltage 380

Valve voltage 24

Weight 320 kg

Dimensions 900x2500x1600

Thanks to its photocell control. The machine is able to stop the filling operation if should any cup not be positioned correctly for filling. The machine accomplishes the process of filling and covering the cups very well that the machine operates without any product loss.

The completed bowls are lined by the conveyor on the arranging table the workers can pick them easily. This system is the most ideal one in terms of handling the product.

Operation System: It drops the plastic bowls automatically. The photocell controls the process of filling and covering the containers. The sealing process is accomplished with the use of heat. Packaging dates are applied in ink and the products are lined up on the table for easy handling.

Capacity 2800 cups / per hour

Voltage 380

Valve voltage 24

Weight 320 kg

Dimensions 900x2500x1600

Main Products

Filling & Sealing Machines